The Power of Air Cannon Manifolds: Transforming the Food Manufacturing Industry

Within the dynamic world of food manufacturing, discovering efficient, cost-effective solutions is crucial. Spraying Systems Air Cannon Manifold (ACM) has superior performance, and is proving itself as the gold standard in effectively dewatering vacuum-packed meat, surpassing the traditional slotted air knives.

23

Feb 24

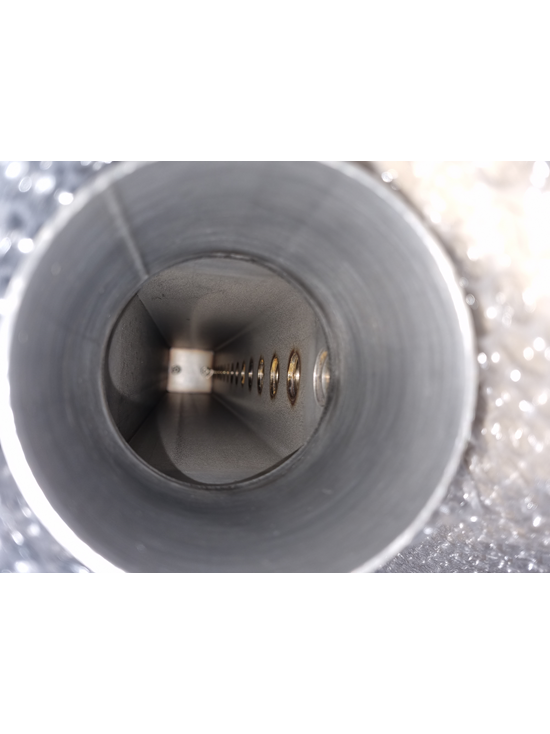

The ACM works by utilising a concentrated force of air to eliminate residual water from meat packs post-shrinkage. After this thorough dewatering process, the packs are securely encased in cardboard cartons, moisture free.

The importance of effective dewatering cannot be stressed enough. Residual moisture on packs can lead to a host of issues, both operational and financial.

Dampness-compromised cartons lead to substantial product handling challenges within the conveyor and sorting systems at cold storage points. This often results in food spoilage. Fixing these problems can not only elevate labour costs but can also lead to conveyor system blockages due to cartons collapsing, further exacerbating inefficiencies.

When pitted against compressed air-supplied air knives or nozzles, ACM units are a clear winner. They drastically curtail operational costs, and our payback analysis demonstrates these substantial savings, potentially exceeding $40k annually!

In addition to its compelling financial benefits, ACM units offer bespoke solutions. Each unit is tailor-made to match the specific application and blower in use, ensuring optimal performance.

Key Advantages

Compared to traditional solutions:

- Exceptional water removal

- Customised to specific applications

Against compressed air nozzles or air knives:

- Unmatched water removal

- Significant operational cost savings

Key Benefits:

- Large reduction in labour costs linked to damp carton handling

- Potential to eliminate costs associated with plastic carton liners

- Decreased operational costs due to compressed air savings

As food manufacturing continues to evolve, the need for smart, efficient, and cost-effective solutions like ACMs will only grow. Their ability to streamline processes, reduce costs, and increase operational efficiency truly sets them apart, marking a new era in food manufacturing. Stay tuned for more insights into how technology is transforming our industry.