Automated Tank Cleaning for Safer Production

16

Sty 26

PROBLEM

A leading wood industry manufacturer needed a safer and more efficient way to clean tanks used for viscous glues.

Previously, employees had to enter the tanks once a month in full protective gear, using high-pressure cleaners to remove residues.

This approach created serious safety risks, as glue vapors still affected workers and summer heat made conditions even worse. It was also time-consuming, taking skilled staff away from more valuable work. The company set a clear goal: to automate cleaning so no one would ever need to enter the tanks again.

SOLUTION

Spraying Systems Co.® worked closely with the manufacturer to identify a reliable automated cleaning system. After an extended testing phase, the TankJet® 190 model proved to be the best fit. While the original version was shorter than ideal, the design was adapted and customized to match the customer's requirements.

The TankJet® system now provides powerful, consistent tank cleaning at scheduled intervals, removing glue build-up without human intervention. By using only clean water, the process avoids additional chemicals and allows for simple recycling through the company's on-site wastewater treatment plant.

Beyond providing the right equipment, Spraying Systems Co.® supported the project with technical guidance and on-site testing to ensure the system was perfectly integrated into daily operations.

RESULTS

The impact was immediate and clear. Manual cleaning was eliminated, meaning no employee is exposed to glue vapors or forced to endure hazardous conditions inside the tanks. Occupational safety has been significantly improved.

At the same time, operational efficiency increased. One employee previously tasked with monthly cleaning could be reassigned to more productive work, improving the use of labor across the business.

A CLOSER LOOK AT THE SYSTEM

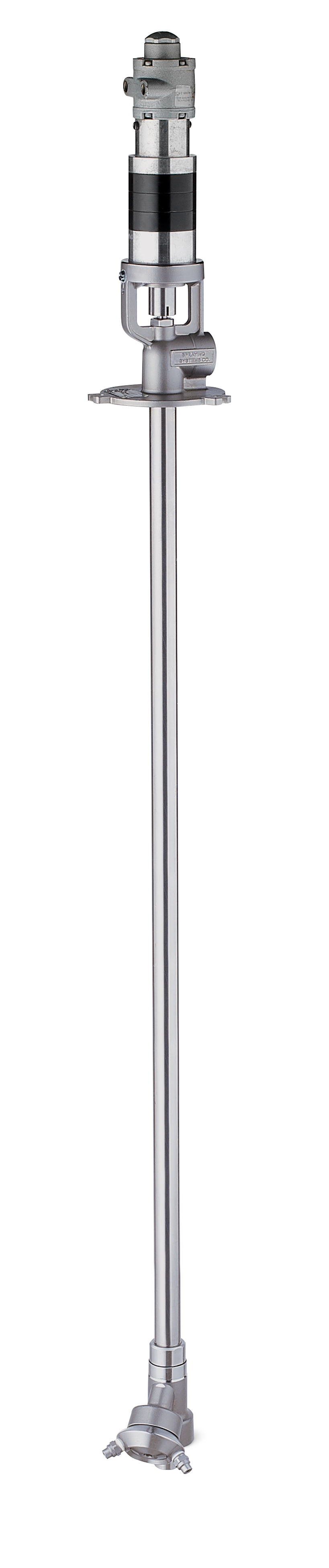

TankJet® 190

It's a robustand efficient tank cleaning unit. Provides powerful spray impact to remove viscous glue residues without requiring manual entry. Reliable operation even under demanding industrial conditions.

Water-only rinsing

It cleans with pure water, avoiding additional chemicals. The rinse water is captured and recycled through the facility's in-house treatment plant, supporting safe and sustainable production.

Automated Cleaning Cycles

Runs at scheduled intervals to keep tanks clean and ready for use. Eliminates downtime from manual washing and ensures consistent, repeatable results with minimal supervision.

Your process could be next! Reach out to see what precision spraying can do for you.