The Engineering Behind The Pneumatic Brush Header

Spraying Systems new Pneumatic Brush Header will change the game in heavy industrial applications in Australia

23

Jun 23

The Concept of a Brush Header

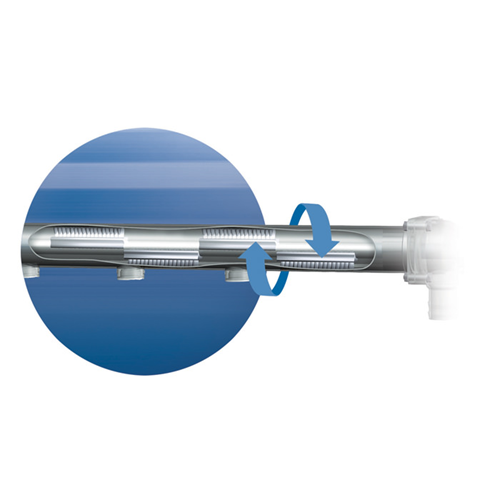

A brush header is an internal rotating brush assembly that fits snugly within a spray bar. The primary role of this component is to ensure the cleanliness of your nozzles, thereby maintaining the efficiency of your spray systems.

Our Brush Headers are designed and fabricated in our Melbourne facility for the tough Australian market.

One of the unique elements of a brush header is its ability to function continuously without necessitating system shutdowns. This innovation serves a dual purpose: firstly, it facilitates uninterrupted operation, thereby curtailing potential downtime that could affect productivity. Secondly, it bolsters safety measures for staff by reducing the need for manual cleaning interventions.

Aside from merely keeping the nozzles clean, the brush header plays a more comprehensive role by effectively scrubbing the interior wall of the spray bar, thereby removing accumulated debris. This debris is then flushed out through a designated valve, which aids in maintaining the overall hygiene and functionality of the spray bar.

Understanding The Pneumatic Brush Header

The Pneumatic Brush Header adds another layer of complexity and efficacy to this technology. This system employs air pressure to control the brushing and cleaning operations. Think of it as an invisible hand that helps maintain the cleanliness and efficiency of your spray bars.

Perfect for use in the following industries:

- Pulp and paper

- Mining

- Sugar mills

- Water treatment

- Food manufacturing

- Any other heavy industrial application

Spraying Systems already offers Electric Automatic and Manual brush header types, and our Pneumatic addition to the range offers flexibility and quality to our customers.

Furthermore, we understand that every engineering application has its unique requirements. Thus, we offer custom-designed brush headers, allowing you to optimize their performance to fit your specific needs. Each Pneumatic Brush Header from Spraying Systems Australia is designed with this intent - to enhance the performance and extend the lifespan of your spray bars.

To engineers and maintenance personal who aim to create a safer work environment, enhance productivity and ensure the longevity of your spray systems, this is a technology worth considering.