Minimize Waste, Maximize Cheese Quality

Applying mold inhibitors in cheese processing is a delicate balance—too much increases moisture and waste, while too little results in mold growth, quality issues, and product loss. Traditional dipping methods and outdated spray systems fail to provide the accuracy and efficiency needed for consistent, cost-effective application.

At Spraying Systems Co., our AutoJet® Food Safety Spray Systems are designed to optimize mold inhibitor application, reducing waste and ensuring precise, uniform coverage. By leveraging Precision Spray Control (PSC) with PulsaJet® automatic nozzles, cheese processors can reduce chemical usage by up to 50%, eliminate over-application, and improve product quality—without adding excess moisture.

Contact Us

Custom-Engineered Spray Solutions for Every Cheese Variety

The Risks of Inaccurate Mold Inhibitor Application

Over-Application & Increased Moisture

Excessive spray application of mold inhibitors creates an environment that is ideal for mold growth, counteracting the very purpose of applying inhibitors. Additionally, most mold inhibitors are expensive, and overuse leads to unnecessary waste without delivering additional protection. This inefficiency not only raises production costs but also increases the risk of product recalls and compliance issues due to improper moisture levels.

Under-Application & Inconsistent Coverage

Applying too little mold inhibitor results in patchy, inconsistent coverage, leaving parts of the cheese vulnerable to mold growth. Without full surface protection, mold spores can take hold in untreated areas, leading to spoilage, quality concerns, and rejected batches. Inadequate application leads to consumer complaints and damage to brand reputation, while wasted inventory adds further financial strain. Ensuring proper dosage and uniform coverage is critical to maintaining product integrity and avoiding costly rework or disposal.

Production Line Variability & Waste

Traditional spray systems lack the ability to adjust in real time to production line speed changes, resulting in uneven mold inhibitor application. When line speeds fluctuate, conventional systems either over-apply or under-apply the inhibitor, leading to waste, inefficiencies, and compliance risks. These outdated methods can cause cheese processors to use up to 30-50% more inhibitor than necessary, increasing operational costs while failing to guarantee consistent, high-quality results.

Clogging & Nozzle Wear from Natamycin

Natamycin, the most commonly used mold inhibitor, contains particulates in some formulations that can clog standard nozzles, leading to reduced spray performance and frequent maintenance interruptions. As nozzles clog, the application becomes inconsistent or completely ineffective, increasing the risk of mold growth and product rejection. The abrasive nature of natamycin also leads to accelerated nozzle wear, requiring frequent replacements that drive up maintenance costs. Without proper nozzle selection, processors face unnecessary downtime, increased labor costs, and costly equipment replacements.

Proven Solutions from Spraying Systems Co.

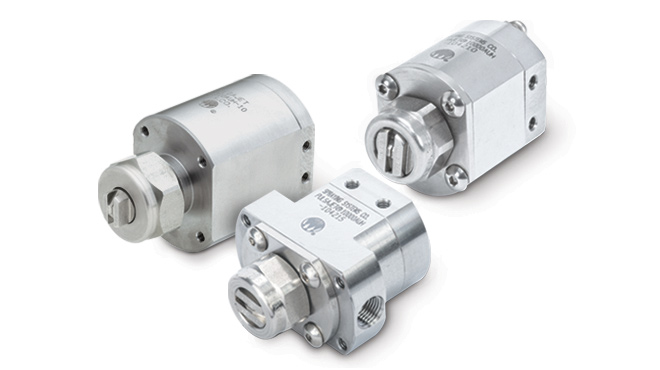

Our AutoJet® Food Safety Spray Systems and PulsaJet® Automatic Spray Nozzles work together to deliver precise, automated mold inhibitor application with minimal waste. AutoJet® Spray Controllers provide real-time control, adjusting spray volumes based on production speed, while PulsaJet® nozzles ensure consistent droplet size and uniform coverage without excess moisture. This combination eliminates overspray, prevents clogging, and reduces mold inhibitor use by up to 50%, ensuring optimal protection for block, sliced, and shredded cheese.

Maximize Cheese Product Quality with Precision Applications

In cheese processing, precise application of mold inhibitors is crucial to ensure product quality and extend shelf life. Spraying Systems Co.’s AutoJet® Food Safety Systems, integrated with PulsaJet® Automatic Spray Nozzles, deliver uniform coverage, reducing waste and enhancing efficiency.

- Precision Spray Control for Consistent Coverage: AutoJet® technology adjusts in real-time to maintain uniform application, preventing gaps and excess moisture

- Reduced Chemical Waste & Costs: Integrated with PulsaJet® nozzles, the system minimizes over-application, cutting mold inhibitor use by up to 50%

- Durable Nozzle Technology: PulsaJet® nozzles are designed for the rigors of dairy processing, ensuring accurate, repeatable dosing and extended operational life

- Seamless System Integration: Compatible with existing cheese processing lines for block, sliced, and shredded cheese

- Sanitary Design & Compliance: Meets food safety regulations, ensuring hygienic operation

Expert Guidance and Ongoing Support

At Spraying Systems Co., we go beyond simply providing nozzles—we offer technical expertise and field support to ensure your process runs at peak performance.

Frequently Asked Questions (FAQs)

Sustainable Practices with Spraying Systems Co.

Spraying Systems Co. is committed to helping dairies and cheese processing facilities adopt sustainable practices by optimizing water usage, reducing cleaning waste, and minimizing environmental impact. Schedule a sustainability assessment to discover cost-saving opportunities and improve resource efficiency with our advanced spray technology.

Contact an Expert

Get Started Today

Spraying Systems Co. is ready to help you optimize your mold inhibitor application process with AutoJet® Food Safety Systems.