case study

How a Food Safety Initiative Improved Worker Safety and Reduced a Bakery's Environmental Footprint

AutoJet® Spray System slashes preservative consumption by 80%, saving $350,000 annually

EXTEND THE SHELF-LIFE OF FRESH BAKED PASTRIES

A large commercial bakery was struggling with applying a preservative to its products. The pastries needed to be completely coated with the preservative to inhibit mold growth. As a result, the bakery was over-applying it. Unfortunately, the preservative settled mostly on the tops of pastries. This had a negative impact on flavor, increased scrap rate and left parts of the pastries at risk for mold growth. In addition, the application process was messy – preservative mist filled the air and settled on equipment. Maintenance time increased, large volumes of the preservative were wasted and the shelf-life of the pastries remained short of goal. The bakery, looking for a company with expertise in food safety, contacted Spraying Systems Co.

During the initial visit to the bakery, our spray experts saw an opportunity to provide a solution that would ensure the preservative was applied properly and help the bakery operate more sustainably. Using our AutoJet® Precision Spray Control (PSC) technology, the pastries could be fully coated using less preservative, scrap could be reduced and worker safety improved.

Solution:

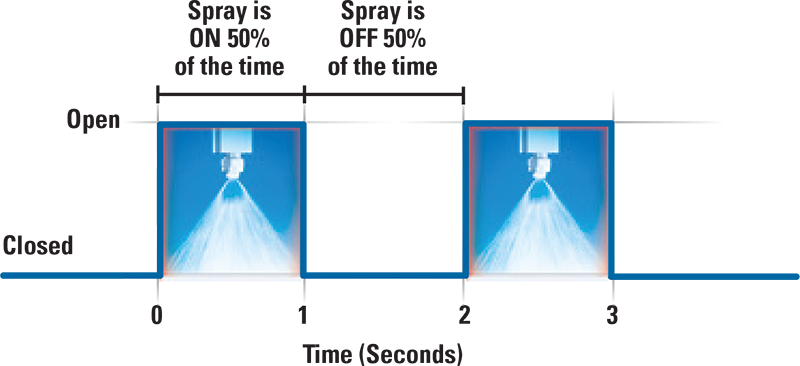

We recommended an AutoJet® Precision Spray Control System consisting of hydraulic PulsaJet® spray nozzles, an AutoJet spray controller and two spray manifolds. Automated control of the preservative application rate ensures the proper volume is applied directly on the pastries. The coverage is precise, uniform and consistent – even when operating conditions like line speed change. PSC technology also eliminates overspray and misting – all the associated safety and maintenance issues. By positioning one spray manifold above the pastries and another below, the pastries are now completely coated with the mold inhibitor. The system also uses a photoelectric object sensor to trigger the nozzles to spray only when pastries are positioned properly in the spray station.

Results:

The single AutoJet® Precision Spray Control System provided a multitude of benefits:

- Pastry shelf-life now meets the goal established by the bakery’s customers

- The bakery has reduced preservative use by 80%

- Product scrap rate has decreased

- A mist-free environment has improved worker safety and dramatically reduced maintenance time

- The bakery’s wastewater treatment load is reduced now that less preservative is being used

The cost of the system was recouped in less than one month and the bakery has reduced operating costs by $350,000 annually. In addition to improving food safety, the bakery is now operating more sustainably and has decreased consumer waste by extending the shelf-life of its pastries.

For complete details of this case study click here to see the PDF version.