AutoJet Precision Lubrication Systems for Automotive Manufacturers

Accurate spray placement with minimal overspray and misting reduces lubricant consumption, decreases maintenance downtime and improves worker safety.

AutoJet® Precision Lubrication Systems Can Significantly Reduce Operating Costs

AutoJet® Precision Lubrication Systems can dramatically improve the accuracy of lubrication applications in automotive operations. Precision Spray Control, featuring fast-cycling PulsaJet® automatic spray nozzles, ensures accurate application of all types of coatings - even tough-to-spray wax-based lubes.

AutoJet® Precision Lubrication System Benefits

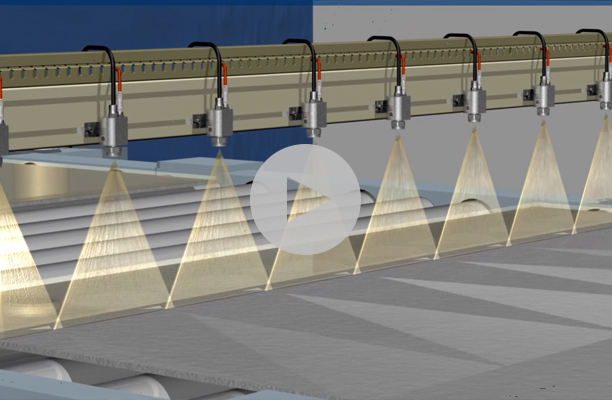

- Applies lubricant precisely where needed - and nowhere else

- Eliminates misting and overspray along with the associated maintenance and safety concerns

- Application rate automatically adjusts when line speed changes

- Zone control enables specific nozzles to be activated, to easily accommodate different sheet widths

See How it Works in Stamping Operations

AutoJet® Precision Lubrication System Benefits

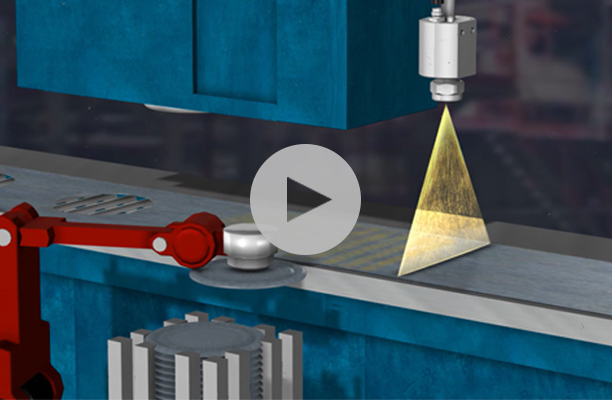

Metal stamping operations can also benefit from Precision Spray Control

- Reduces the consumption of costly lubricants

- Eliminates misting and overspray along with the associated maintenance and safety concerns

Eliminates mis - Application rate automatically adjusts when line speed changes

- Improves worker safety