OPTIMIZING SPRAY TECHNOLOGY FOR

MINING

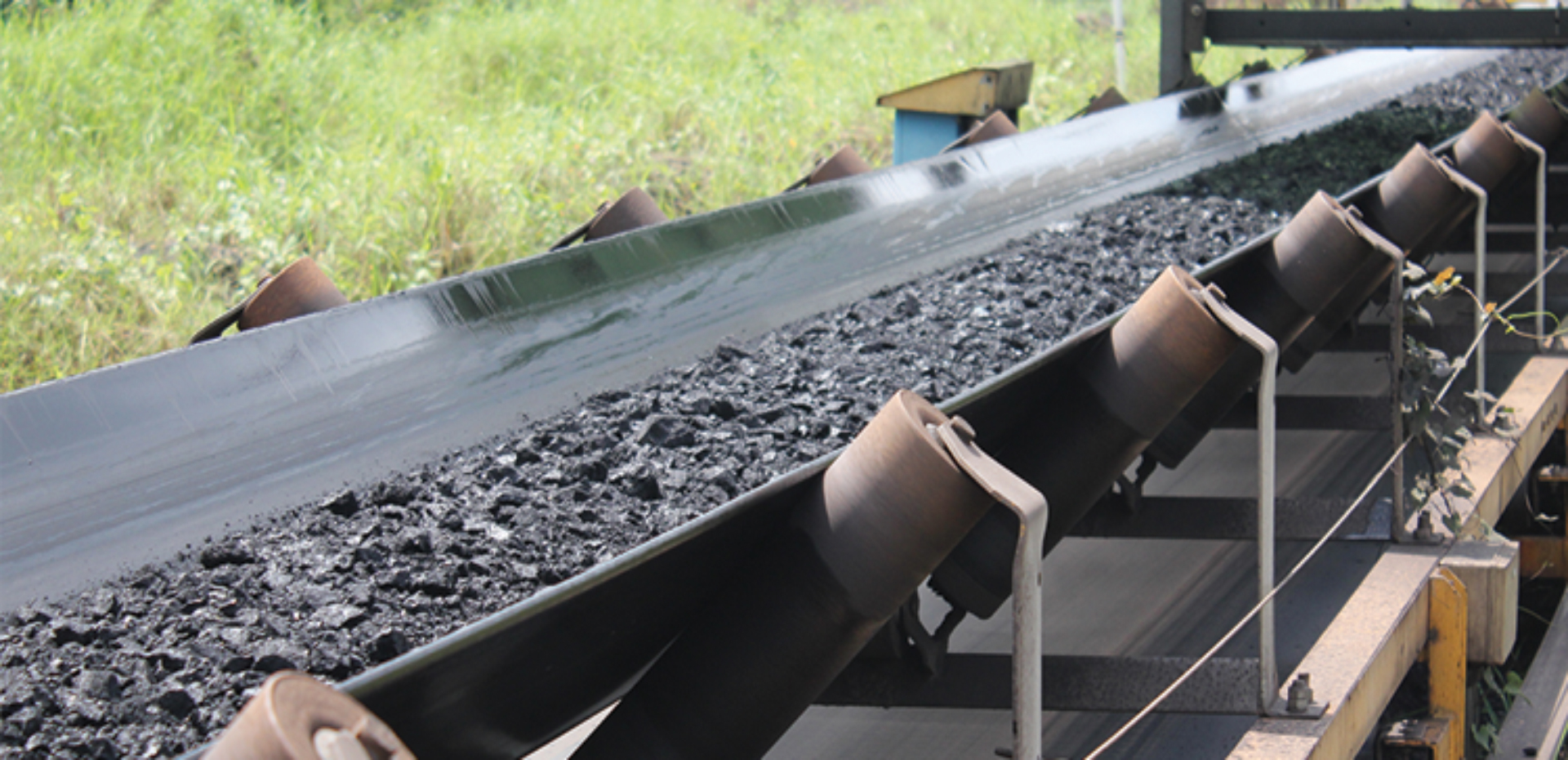

Mining operations around the world strive to improve production output, minimize waste and reduce downtime. Maintaining spray nozzle performance is critical for both dust prevention and dust suppression. A common misconception is that if nozzles are still capable of spraying, they are functioning properly – this is far from the truth. Dust can significantly impact the efficiency of your operations and affect the health of your employees.

Mining Success Stories

Keeping Workers and the Environment Safe

Spraying Systems Co. provided an effective dust control system for rail car unloading using hydraulic nozzles.

2-week PAYBACK ON INVESTMENT IN WATER SPRAY TECHNOLOGY

Spraying Systems Co. installed air atomizing nozzles to suppress dust, dissipate methane gas and prevent ignition.