Frozen Pizza Manufacturer Reduces Soybean Oil Waste with Automated Spray System

Frozen Pizza Manufacturer Reduces Soybean Oil Waste with Automated Spray System

Manufacturer saves more than US$50,000

Problem:

A private label manufacturer of frozen pizzas needed to apply soybean oil to dough before it was baked and formed into crusts. It was important to apply a precise coating of oil to maintain a consistent calorie count.

The system in use pumped soybean oil through a stainless steel trough equipped with a series of needle valves. The needle valves were adjusted manually to control the flow of oil onto the dough and a stainless steel rod was used to spread the oil across the dough. The amount of oil applied varied widely from batch to batch making it impossible to validate the calorie count of the finished product. Plus, oil leaked off the edges of the dough – wasting a great deal of this costly ingredient and causing excessive wear to the conveyor belt.

Solution:

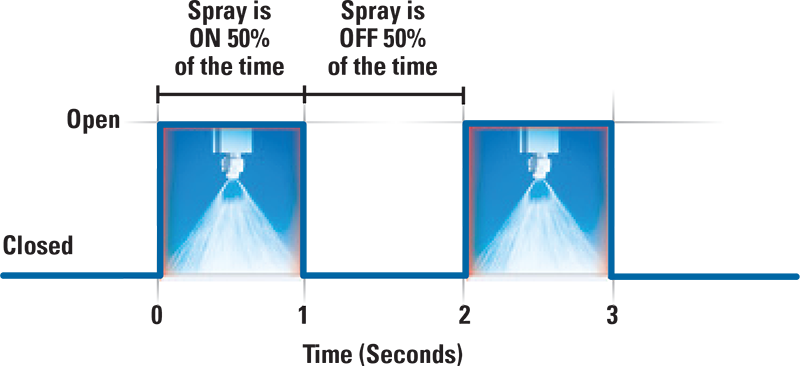

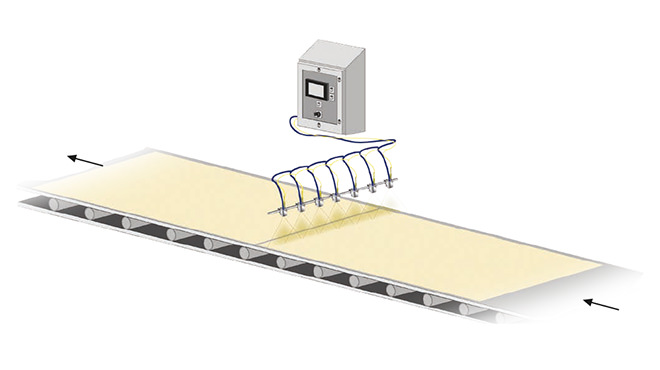

The Spraying Systems Co. solution uses an AutoJet® Spray System with PulsaJet® automatic spray nozzles. Operators select an oil application rate on the control panel based on the specific pizza recipe being produced. The PLC-based system also allows operators to easily activate specific nozzles in order to match spray coverage to the width of the dough being processed. During operation, Precision Spray Control (PSC) automatically adjusts the flow of soybean oil from the nozzles to accommodate line speed changes.

Results:

The AutoJet® Spray System ensures consistent application of the soybean oil across the width of the dough and eliminates a great deal of waste – more than US$38,000 of soybean oil in a single year. The manufacturer also saved US$13,000 on conveyor belt replacement. In addition to the economic benefits, calorie count for the pizzas can now be validated – an important product quality measurement for the customers buying and reselling the pizzas under various retail brands.

For complete details of this case study, click here to see the PDF version.