The system optimizes the performance of automatic spray nozzles for an efficient use of resources and a high quality end result. Due to the modular nature of the E2850+ there are no limits to the number of spray nozzles that can be controlled for your spray process.

There are limitless possibilities with spray applications so the E2850+ offers a large variety of options as standard:

- To improve integration and usability the system uses a Siemens PLC System. This allows remote connection and control to the system

- The set-up of all of the parameters can be done on the touch panel.

The AutoJet® E2850+ Spray System can be used as an autonomous spray system or can be integrated into any existing process control system.

AutoJet® E2850+ Spray Controller Advanced Features Explained

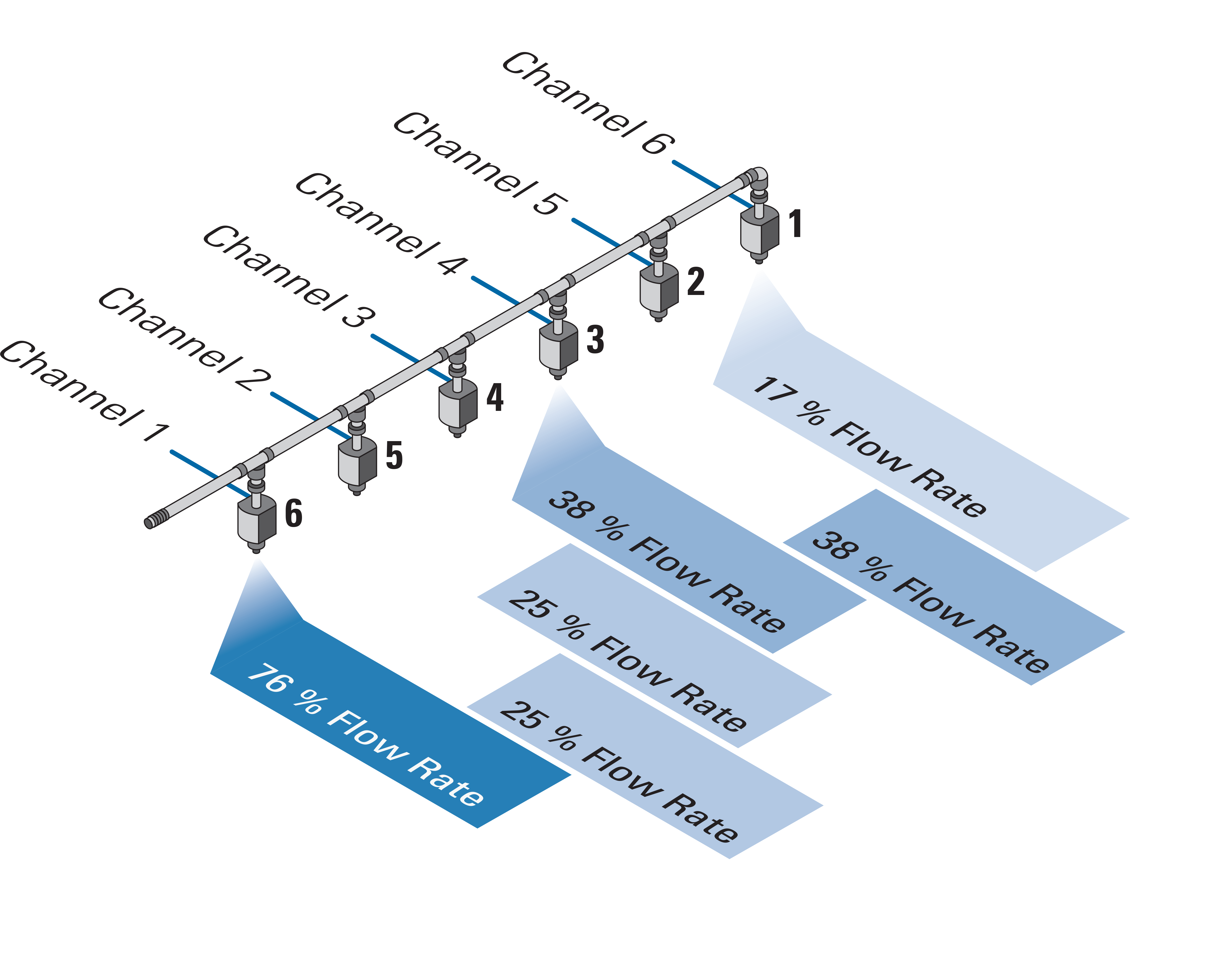

LIQUID PRESSURE MEASUREMENT

The liquid pressure to the nozzles is measured by the pressure sensor. Warnings are generated when the measured value is outside minimum/maximum limits or when a sensor error occurs. Flow through an orifice is dependent on applied pressure. By measuring the pressure change, it is possible to calculate a new theoretical duty cycle to compensate for flow differences caused by pressure differences.

SYSTEM INTEGRITY

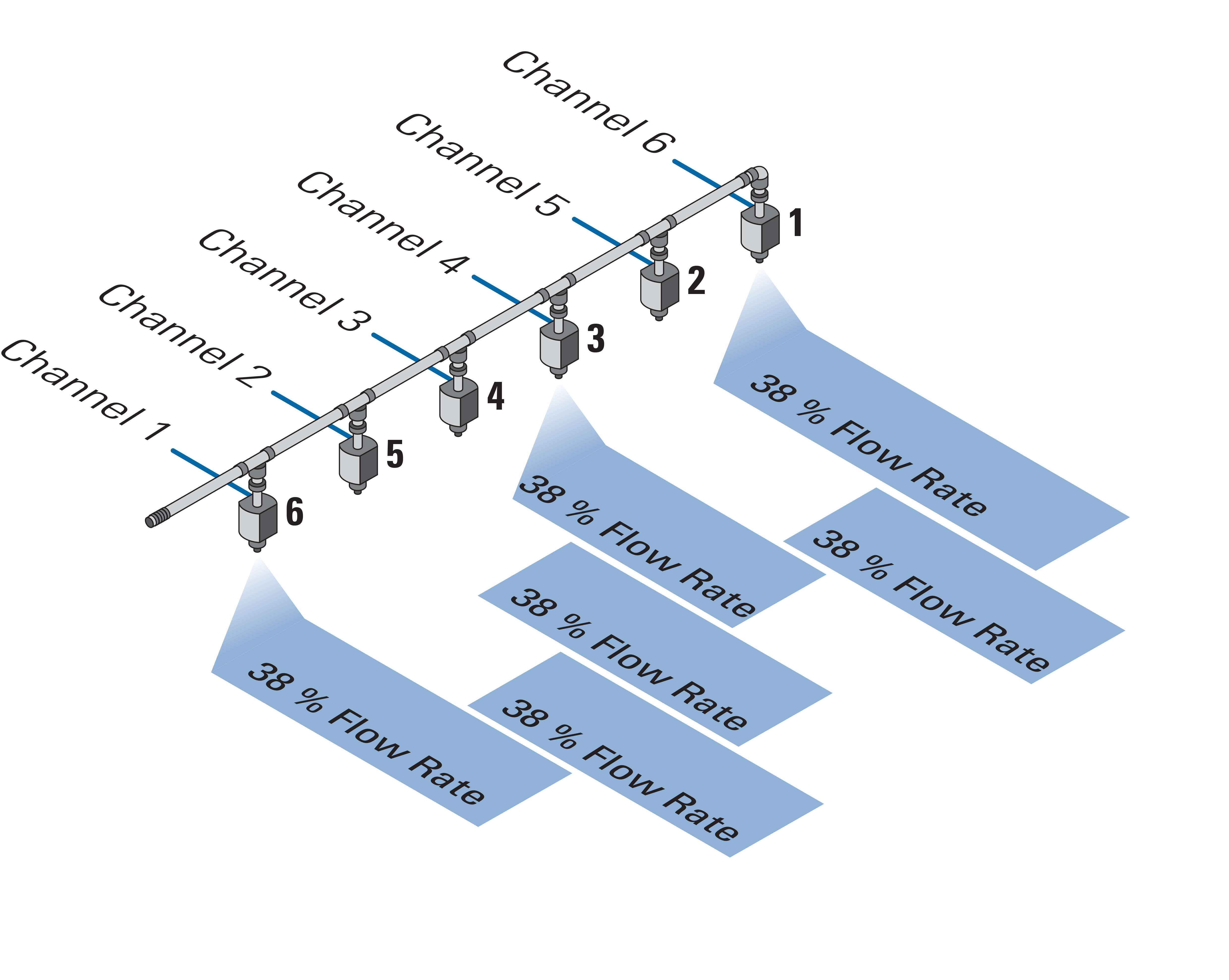

This feature ensures reliable spray performance by continuously checking for deviations in spray performance. It detects issues such as clogged or worn nozzles, helping maintain consistent application, reduce waste, and extend system longevity.

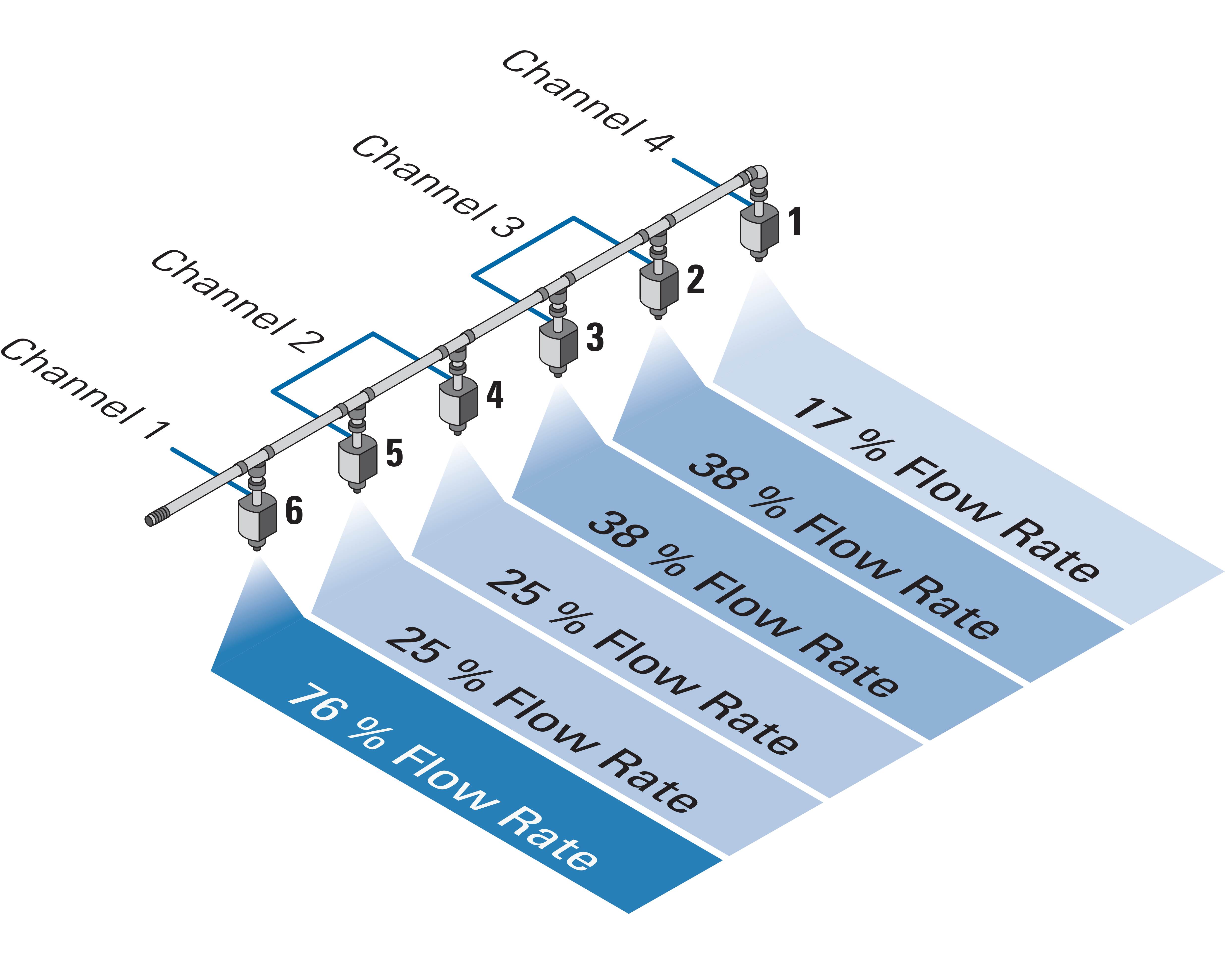

CLOSED-LOOP FLOW CONTROL

With closed-loop flow control the liquid flow to the nozzles is measured by the flow sensor. Warnings are generated when the measured value is outside minimum/maximum limits and automatically compensates for changes in flow rate. The flow meter is used to make sure the required amount of liquid is sprayed. This allows:

- Automatic nozzle calibration

- Closed loop flow regulation

RINSING & PRIMING

This feature enables the customer to automatically switch to a cleaning agent or any other liquid of choice. The draining and cleaning of the entire liquid line and its nozzles - to prevent clogging - are also automated. Additionally, the system’s rinsing function can be activated manually or automatically after a specified period of inactivity.