Spray Drying Nozzles

Spray Drying Nozzles

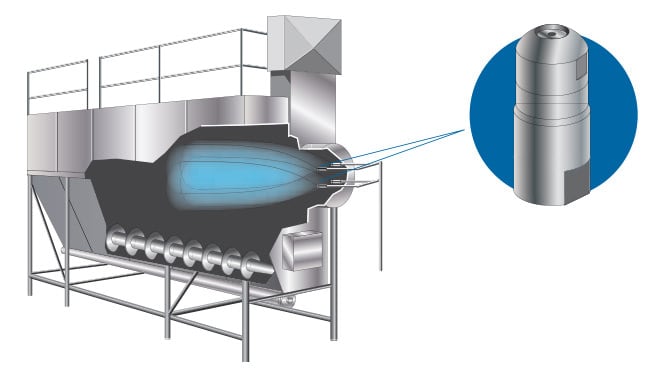

For spray drying products ranging from food items and pharmaceuticals to detergents, pigments and fine chemicals, depend on SprayDry® nozzles from Spraying Systems Co.

The Broadest Range of Spray Drying Nozzles

SprayDry® nozzles are available for spray drying all types of products including milk, whey, coffee, yeast, spices and infant formula; soaps and detergents; dyes and pigments; fine chemicals; and pharmaceuticals.

Look to our spray dry experts for help selecting the right SprayDry nozzle for your specific operation. Our SprayDry nozzles offer:

-

Quick delivery

-

Long wear life to extend production runs

-

Maximum free passage designs to reduce clogging

-

Hand-tight designs to eliminate the need for special tools and reduce maintenance time

-

Several nozzle styles, easily configured to exact performance specs

-

Hundreds of interchangeable components to ensure precise drop size

An overview of our SprayDry® nozzle product line is provided below. Use our SprayDry Nozzle Selector to quickly find nozzles that will deliver the exact performance you need based on your desired flow rate, operating pressure and the specific gravity of your feed stock.