Leading Non-Woven Products Manufacturer Saves Over US$170,000 Annually with Spray System

Leading Non-Woven Products Manufacturer Saves Over US$170,000 Annually with Spray System

Problem:

Fibrix, a leading manufacturer of non-woven products, needed to apply a binder coating to its HVAC filtration products. The spray system in place only provided a 60% transfer rate, generated a large amount of overspray and produced an excessive amount of misting. This process wasted valuable coating, created safety and environmental issues, required extra maintenance time and necessitated the installation of a costly mist extraction hood. In addition, the spray system could not be used for multiple products. In order to accommodate the coating-per-square-inch requirements, a manual change of spray tips was necessary. This required stopping the conveyor, creating a significant amount of downtime.

Solution:

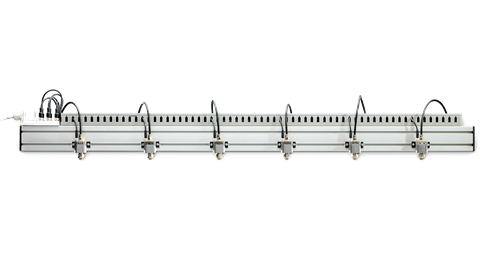

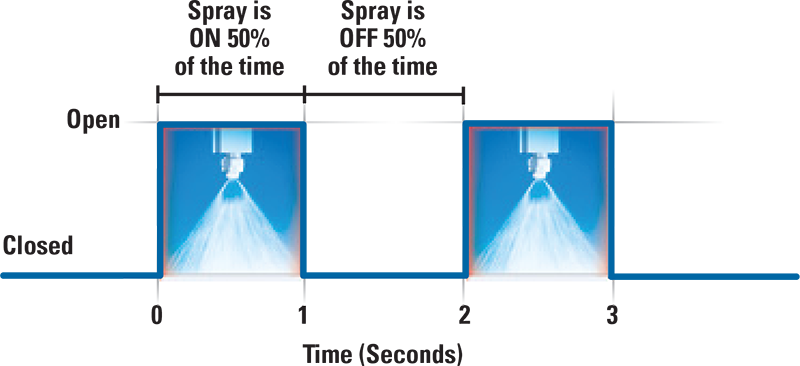

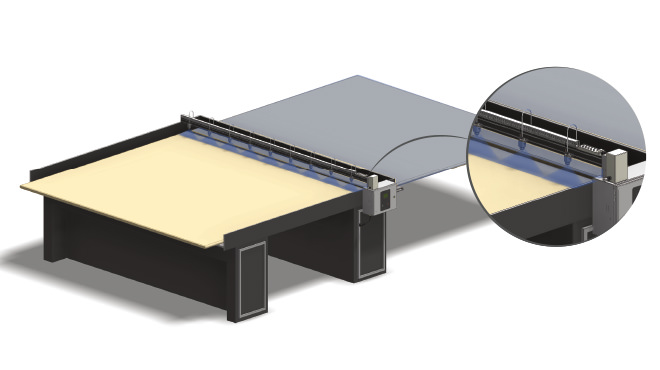

Fibrix now uses an AutoJet® Model 2008+ Modular Spray System with Precision Spray Control (PSC). As the filtration product sizes change, PSC allows precise regulation of binder coating flow rates and eliminates the need for conveyor stoppage to manually change the spray tips. The system also includes a 96" (2438 mm) wide 98250 spray manifold equipped with nine hydraulic PulsaJet® AA10000AUH-104210 automatic spray nozzles. These hydraulic nozzles provide a larger drop size to minimize misting. The manifold and nozzles are operated by a Zone Control Panel. The panel allows the selection of all nine nozzles, for full-width coverage, or just the center seven or center five nozzles for narrower mat widths. This greatly reduces the amount of binder coating waste and labor to remove the excess.

Results:

The AutoJet® spray system’s reduction of overspray and elimination of misting provides Fibrix with a transfer rate increase of 35% and a 25% reduction in chemical costs. With conveyor stoppage down to a minimum, production is up 10%. The system eliminates spray-related safety and environmental issues and the need for the costly mist extraction system. The company’s savings is US$170,000 annually with a system payback period of only two months. Fibrix ordered three more systems and plans to add systems in the future.

For complete details of this case study click here to see the PDF version.