Case Study

Cheese Manufacturer Slashes Mold Inhibitor Use in Half

Saves $143,000 annually with an AutoJet® food safety spray system

Problem:

A cheese manufacturer needed a better way to apply a costly mold inhibitor – natamycin – on blocks of cheese on a moving conveyor. The natamycin was applied to the cheese as it passed through a spray station but the manufacturer was struggling to apply the proper volume. Over-application was wasteful; under-application resulted in increased mold counts. In addition, the nozzles sprayed continuously – even between the blocks of cheese, adding to the waste issue.

Solution:

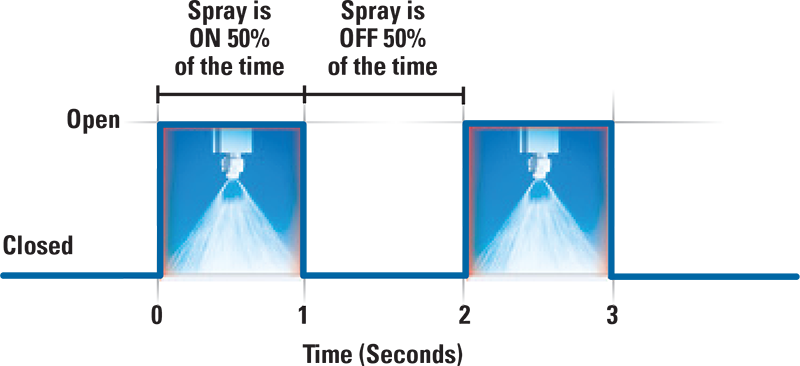

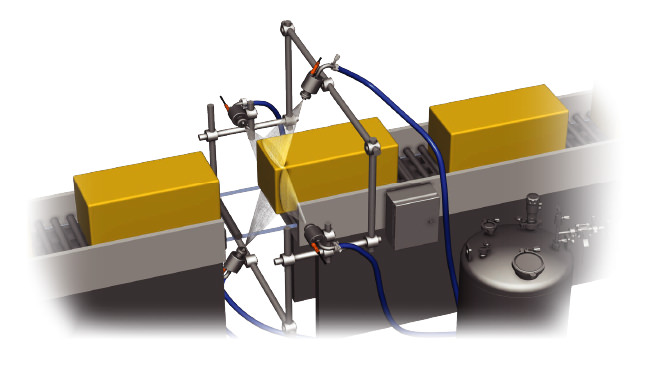

Spraying Systems Co. solved the problem with an AutoJet Food Safety Spray System for Cheese. A single system now applies the natamycin to cheese on two lines. Each line has four hydraulic PulsaJet® electrically-actuated spray nozzles, strategically placed to apply the natamycin uniformly on all sides of the cheese without waste. Precision Spray Control (PSC) is used to ensure the proper volume of natamycin is applied – even when operating conditions such as line speed changes. The spray controller makes automatic adjustments to the flow rate, eliminating over- and under-application problems. Object sensors are used to detect when cheese blocks are in the spray station. The nozzles are triggered to spray only when the cheese blocks are in the proper position.

Results:

Use of the AutoJet Food Safety Spray System has reduced natamycin consumption by nearly 50% – a savings of US$143,000 per year. The cost of the system was offset in less than five months. In addition to the ongoing cost savings, the manufacturer is no longer plagued by unacceptable mold counts.

For complete details of this case study click here to see the PDF version.