Automated Antimicrobial Intervention Maintains Food Safety and Saves Processor US$300,000 Annually

Automated Antimicrobial Intervention Maintains Food Safety and Saves Processor US$300,000 Annually

Problem:

Old World Provisions is a meat processor specializing in whole muscle products and roll stock products. It wanted to reduce the expense of the functional ingredients used as antimicrobial agents in products and were using an antimicrobial that cost US$0.025 to US$0.030 per pound. In addition to expense control, maintaining shelf life and achieving a clean label were also important.

Solution:

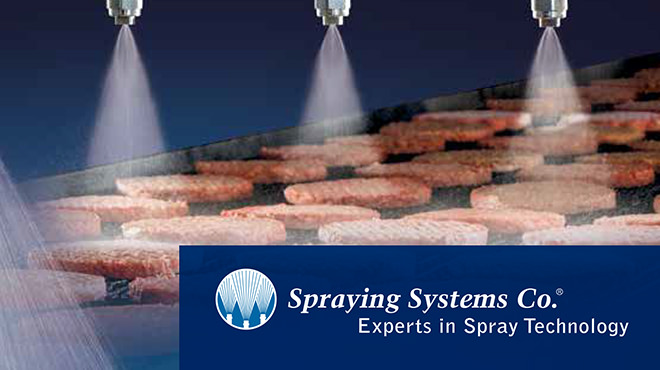

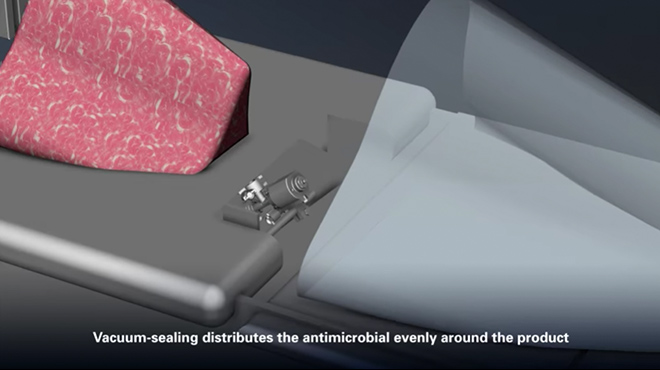

The Spraying Systems Co. solution was an AutoJet® Antimicrobial Spray System using the SLIC (Sprayed Lethality in Container) process. The SLIC process is a food safety intervention which entails spraying an antimicrobial into a vacuum package before the meat product is inserted. Vacuum-sealing of the package distributes the antimicrobial evenly around the product – a process that has been proven effective by the USDA/ARS.

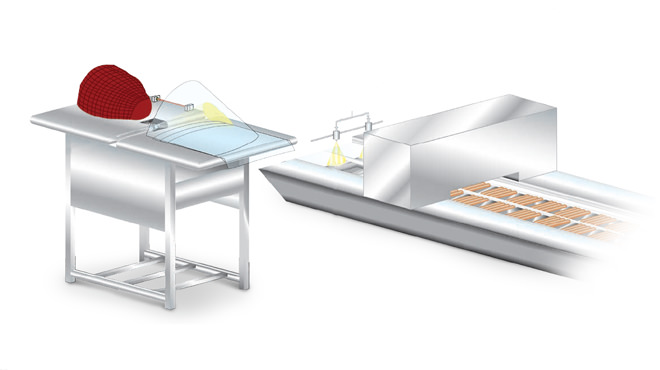

A 2-channel AutoJet System controls spray application of the antimicrobial agent on both a roll stock line and on a bagger operating at 6 packages per minute. The system’s spray controller provides easy access to multiple recipes which allows antimicrobial shot sizes varying from 2 – 40 ml to be sprayed into the packages. Custom PulsaJet® automatic spray nozzles constructed of FDA-approved CrN (chromium nitride) precisely dose the antimicrobial agent – in this case, lauric arginate diluted in a clarified liquid smoke. SprayCheck™ sensors are used to confirm that each package receives the proper dosage.

Results:

Since the AutoJet® Antimicrobial Spray System was installed, Old World Provisions has maintained ALT-2 status with typical log reductions ranging from 1.8 to 2.8 for roll stock and whole muscle products. Product quality and shelf life have remained consistent. Product labels are clean since lauric arginate is a bacteriocide that is also considered a processing aid and does not need to be labeled at the levels being used. The application cost of the lauric arginate and liquid smoke flavor is just US$0.015 per pound. Annual savings for Old World Provisions is US$300,000 per year.

For complete details of this case study, click here to see the PDF version.