Fruit Packer Improves Packaging and Saves US$36,000 Using Automated Spray System

Fruit Packer Improves Packaging and Saves US$36,000 Using Automated Spray System

Problem:

A large grower and packer of stone fruit needed to apply a fi ne mist to peaches immediately before applying produce stickers and sealing the shipping cases. The moisture helps the stickers adhere to the fruit.

A manual misting process was being used. The misting was inconsistent and labor intensive. Some stickers fell off the fruit and created a quality control problem. In addition, the repetitive use of a handheld spray bottle by workers raised concerns about carpal tunnel syndrome.

Solution:

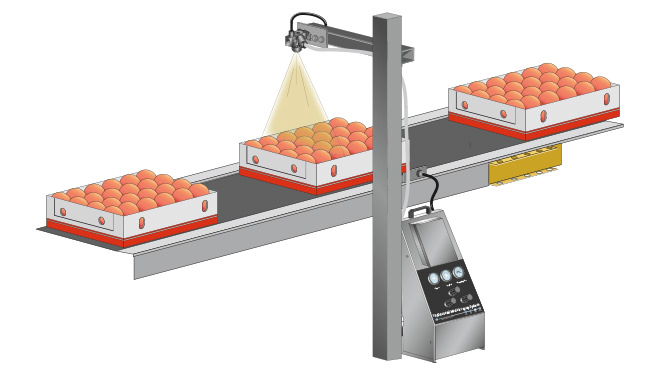

Spraying Systems Co.’s solution uses an AutoJet® Model 1550 Modular Spray System with an electrically-actuated spray nozzle to apply a fi ne mist to the peaches. Triggered by a proximity switch, the spray controller activates an AA250AUH automatic nozzle which is mounted above the packaging line. The nozzle produces a consistent mist, eliminating over- and under-wetting problems.

Results:

Produce stickers adhere more consistently to the packed fruit and the risk of causing repetitive use injuries to workers has been eliminated. Eight packing lines now use AutoJet® Modular Spray Systems. As a result, the packer’s operating costs have been reduced since the need for manual labor for misting has been eliminated. Each season, labor costs totaled approximately US$36,000 – significantly more than the total investment for the new spray systems. The AutoJet Spray Systems paid for themselves in less than three months and will continue to operate efficiently for many years.

For complete details of this case study click here to see the PDF version.