applications

descaling

Our global manufacturing capabilities, factory support staff and decades of experience uniquely qualify us to solve your descaling challenges. Take advantage of our local sales engineers that specialize only in spray technology.

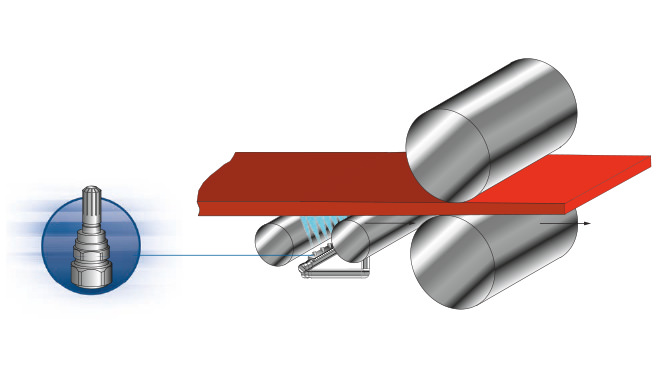

DescaleJet Pro+ Nozzles

Patent-pending design optimizes flow stability for greater impact and smooth, streak-free surfaces.

- Local support: Our steel specialists are in your area and ready to help. They’re backed by our regional spray technology centers equipped with a variety of testing equipment.

- Performance validation before you purchase: We’ll measure impact and coverage of the DescaleJet Pro+ and your current descale nozzles using your operating conditions in our spray labs. Understand the performance gains before you buy.

- Competitive pricing: Better performance and a lower cost? Yes!

- Quick, local delivery: Robust manufacturing at our factory in the USA means delivery of DescaleJet Pro+ nozzles in days, not weeks or months. Protect against supply chain disruption by working with a local supplier.

- Wear life testing: Testing in our lab will determine the optimal replacement interval for DescaleJet Pro+ nozzles to prevent quality problems due to slight changes in impact and coverage.

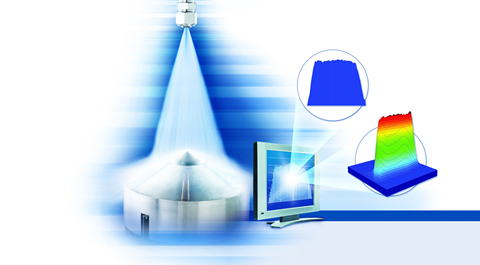

Advanced Laboratory Services are Key to Improving Your Descaling Performance

- Proprietary DescaleWare software bases descaling header design on user-specific operating conditions

- Impact and coverage testing with proprietary equipment in our labs validates actual descaling performance

- Theoretical impact and coverage calculations are only a baseline

- Computational Fluid Dynamics (CFD) validates spray performance for descaling nozzles and headers in complex applications

Broad Range of Descaling Nozzle Options

Rely on DescaleJet nozzles for long service life and easy maintenance. Our entire range of descaling nozzles provides:

- High-quality descaling resulting in smooth, streak-free surfaces

- Efficient use of energy and water to reduce operating costs

- Long service life to minimize nozzle expense

- Easy maintenance and tip replacement to reduce labor costs