Truck Wash Reduces Water Use by 40% with TankJet Equipment

Truck Wash Reduces Water Use by 40% with TankJet Equipment

A tanker truck cleaning facility needed to replace high-maintenance tank cleaning devices in all 10 of its cleaning bays.

Problem:

A tanker truck cleaning facility needed to replace high-maintenance tank cleaning devices in all 10 of its cleaning bays. Each device required frequent repairs – averaging more than US$3,500 annually in parts and labor. Lost production time due to maintenance downtime cost an additional US$7,000 each year. Long cycle times for cleaning – about 24 minutes used 2,040 gallons (7722.2 liters) of water. The facility was cleaning approximately 25,000 tank trucks per year, so water consumption was a very important consideration.

Solution:

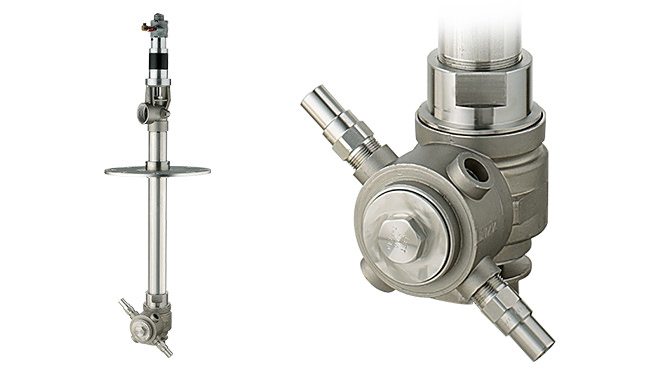

TankJet AA290 tank cleaners have been installed in each cleaning bay. Each tank cleaner has two nozzles, which rotate 360° to provide complete coverage. Unlike fluid-driven tank cleaners which tend to clog when debris passes through the gear train, the TankJet AA290 tank cleaner is powered by an electric motor to ensure dependable rotation and long-term performance. The motor is positioned outside of the tanker truck for safety.

Results:

The TankJet AA290 tank cleaners have a dramatic impact on the tanker truck cleaning facility. The cost of the new TankJet AA290 tank cleaners was recouped in less than one year. Downtime for frequent, costly repairs has been eliminated. The TankJet AA290 tank cleaners perform reliably day-in and day-out with minimal annual maintenance. Cleaning cycles are now completed in 16 minutes instead of 24 minutes allowing more trucks to be cleaned on a daily basis. In addition, water use for each cleaning cycle has decreased by 40% for an annual savings of more than 20 million gallons (75.8 million liters). Reduced water use has also resulted in reduced chemical and energy use and lower wastewater disposal costs. The cost of the ten new TankJet AA290 tank cleaners was recouped in less than one year.

For complete details of this case study click here to see the PDF version.