New Blower System Reduces Moisture Hazards for Deli Meat Packager

New Blower System Reduces Moisture Hazards for Deli Meat Packager

Problem:

A Midwest deli meat company was experiencing difficulty with the performance of compressed air knives installed at three of its locations. The air knives were mounted 10" (254 mm) above conveyors leading out of steam tunnel and were designed to dry the meat packages before packing them in cardboard boxes. Residual moisture was not being properly blown off the meat packages and this led to concerns about compromised cardboard box integrity and possible mold growth between meat packages. The company needed a new system that would install easily, handle various-sized meat packages and reduce the instance of wet boxes to near zero.

Solution:

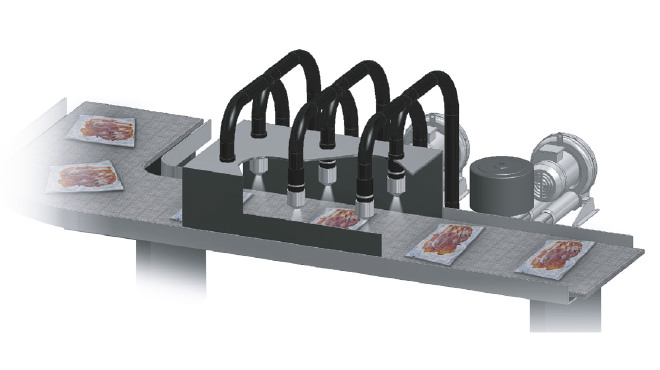

Following a series of successful, small-scale demonstrations at a couple of the packager’s locations, Spraying Systems Co.’s WindJet® blower system was selected and wall-mounted in each of three facilities to help minimize the equipment’s footprint. Each system included a “Y” adapter to split air flow from the blower and two manifolds to further split the air to a total of six air cannons. Mounting brackets were used to position the air cannons for more strategic placement and aggressive air blow-off action.

The WindJet system uses a low-noise, low-maintenance regenerative blower, which is extremely energy efficient and produces clean, heated air. The air cannons deliver uniform, high-velocity air streams that easily blow moisture from the contours and crevices of the meat packages.

Results:

The meat packaging company began realizing the benefits of the WindJet® blower systems immediately. The systems significantly improved the moisture blow-off, reducing the number of wet boxes and the time required to re-pack them. Savings from the reduction in packaging costs and the elimination of compressed air generated a payback period of only 10 months for the WindJet systems. In addition, when compared to the compressed air knives previously used, the WindJet solution contributed significantly to the company’s sustainability efforts.

For complete details of this case study click here to see the PDF version.