Industrial Paper Manufacturer Saves US$50,000 Annually with AutoJet® Spray System

Industrial Paper Manufacturer Saves US$50,000 Annually with AutoJet® Spray System

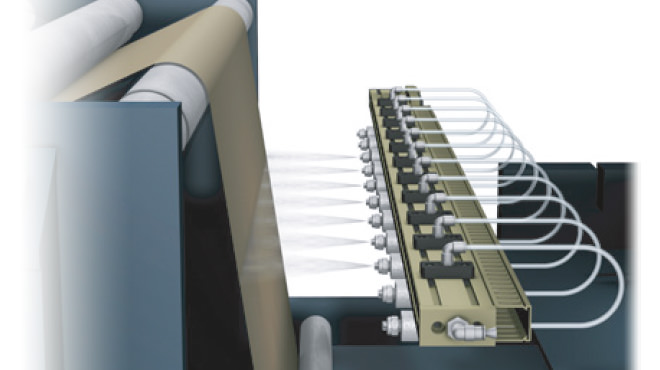

An AutoJet spray system with zone control is now used to ensure proper moisture addition. The spray controller monitors the moisture level of the sheet and other operating conditions such as line speed.

Problem:

A manufacturer of specialty papers was receiving complaints because of rolled paper edge-curling during storage. About 30% of the rolls produced per line needed secondary trimming after shipment, which required labor and created scrap or the rolls had to be replaced. Customer loyalty and future sales were endangered. The manufacturer determined that more moisture needed to be added to the paper prior to rewinding.

Solution:

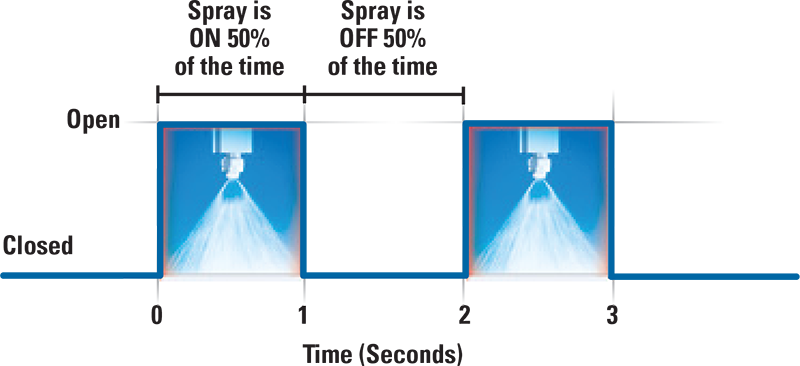

An AutoJet spray system with zone control is now used to ensure proper moisture addition. The spray controller monitors the moisture level of the sheet and other operating conditions such as line speed. Using closed loop control, automatic adjustments to flow rate are made to ensure the proper volume of moisture is applied to the sheets.

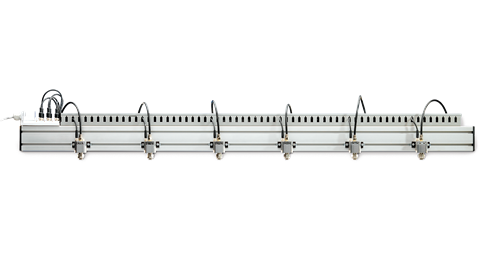

PulsaJet® electrically-actuated spray nozzles are mounted on a manifold and grouped into independently controlled zones for operating flexibility. The nozzles in the center are active for all sheet widths. When sheet widths from 40 to 48 inches (102 to 122 cm) are run, additional nozzles to the left and right of center nozzles spray. For sheet widths from 50 to 62 inches (127 to 157 cm), all the nozzles operate to ensure full coverage.

Results:

The precise application of moisture by the AutoJet spray system prevents the rolled paper edges from curling during storage and eliminates the need for secondary trimming or roll replacement. The manufacturer estimates a savings of US$50,000 annually since the installation of the system. In addition, customer satisfaction has improved dramatically. The projected payback period for the system is about 18 months.

For complete details of this case study click here to see the PDF version.