Coal Producer Improves Safety and Opens New Mining Areas with Advanced Spray Technology

Coal Producer Improves Safety and Opens New Mining Areas with Advanced Spray Technology

Problem:

A leading coal producer in the United States needed to dissipate methane gas in an under-ground mine to eliminate the possibility of ignition. Certain areas of the mine near methane well sites were considered unsafe because of the higher concentration of methane gas. Saturating the air to a specific humidity prevents the methane from igniting. The hydraulic nozzles used on the continuous miners were unable to produce the small droplets required to humidify the air.

Solution:

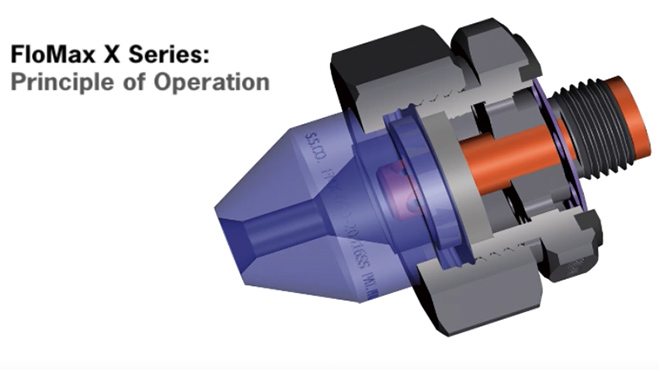

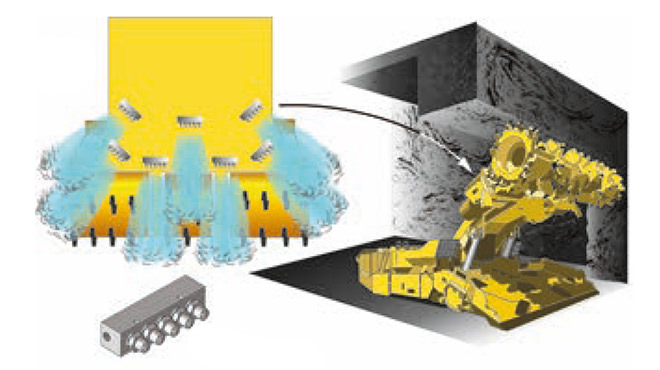

Spraying Systems Co.’s FloMax® air atomizing nozzles provided the ideal solution for this coal producer. FloMax nozzles produce very small droplets at low flow rates for effective dust control and humidification – between 40 and 60 microns. The nozzles are mounted on the continuous miner in seven banks of five nozzles each. During operation, these nozzles create a curtain of fine mist that suppresses dust, dissipates the methane gas and prevents the possibility of ignition.

Results:

FloMax® air atomizing nozzles have improved safety in the mine and allowed the coal producer to mine areas that were previously untapped. Because the production value of a single continuous miner can far exceed US$50,000 per day, the additional coal produced in the mine resulted in a payback period of less than two weeks. Since the original installation, three additional continuous miners have been equipped with FloMax nozzles.

For complete details of this case study click here to see the PDF version.