Problem:

Alpha Aluminum is a manufacturer of aluminum foil used primarily in flexible packaging applications. The company produces coils of ¼ inch (6 mm) strip in widths from 32 to 60 inches (813 to 1524 mm) that are cold-rolled into foil. The company needed to increase production speed but was limited by the aluminum sticking to the caster rolls. Previously, personnel used handheld spray guns and bottles to apply the release agent to the rolls at the start of each cast, but spray coverage was inconsistent, and the release agent was ineffective. This method also created a mess due to over-application.

Alpha Aluminum required a spray solution that would consistently and evenly apply a water-based suspension of graphite to 60 inch (1524 mm) wide caster rolls.

Solution:

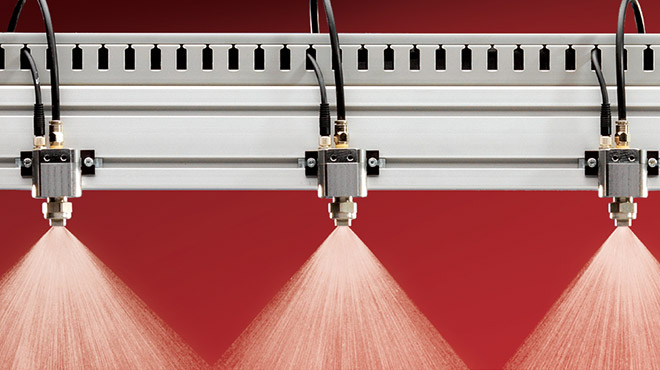

Spraying Systems Co.’s AutoJet® Model 2008+ Modular Spray System solved the problem. The system applied a light, uniform coat of the graphite release agent to the caster rolls through two 98250 headers. Eight PulsaJet® AA10000JAU air atomizing nozzles were equipped with drip-free, flat spray set-ups. When producing 60 inch (1524 mm) wide sheet, three-zone control allowed selection of all eight nozzles for full width coverage. For narrower sheets, the center four or six nozzles could be selected.

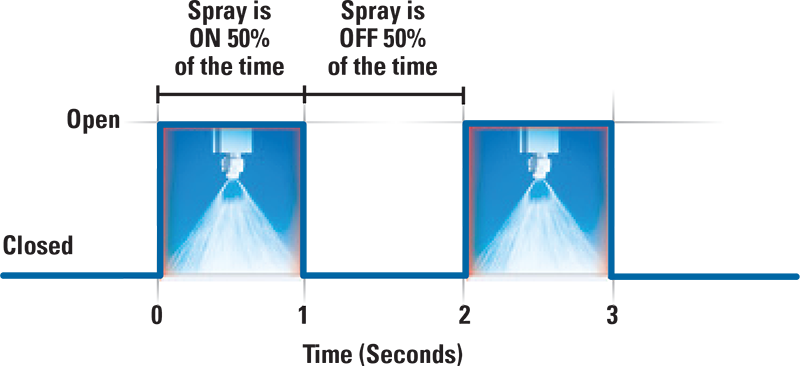

The drip-free spray set-ups and the ability to precisely control the rate of application helped the graphite stay in place on the hot rolls, while the water evaporated, leaving no messy runoff. Precision Spray Control (PSC) ensured the spray pattern and distribution did not change as the application rate was adjusted as needed, keeping the freshly cast, hot aluminum sheet from sticking to the rolls.

Results:

Installing the AutoJet® Model 2008+ Modular Spray System greatly reduced Alpha Aluminum’s sticking problem, enabling faster casting and increasing production by 17%. Combining that increase with reductions in labor and release agent consumption, they realized a payback period of less than four months.

The system also improved their facility’s sustainability by reducing graphite usage as well as eliminating overspray and the environmental concerns that came with it. Automating the release agent application also kept operators from having to spend any more time than necessary working close to the hot rolls and molten metal.

For complete details of this case study, click here to see the PDF version.