What is the difference between Dust Prevention and Dust Suppression

1

Jun 22

Dust control is a major issue on mining sites as excessive dust can cause health and safety problems, cause your equipment to erode and breakdown, and reduce efficiency. Spraying systems has a range of products that can be tailored to solve these issues on your site.

The first and most important question you need to answer does want to prevent or suppress the dust at each application. This is what we mean by the terms dust prevention and dust suppression.

DUST PREVENTION

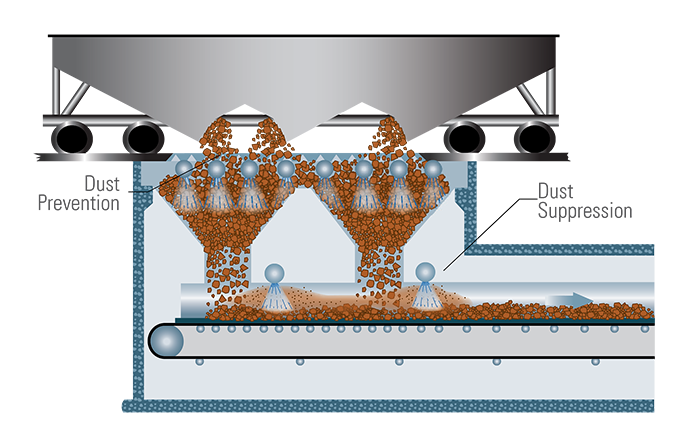

Dust prevention refers to the principle of adding water to ore to control the problem at the source and prevent dust particles from becoming airborne. When the material absorbs moisture, it increases the mass and weighs the particle down. When applied correctly, this is a practical and straightforward application that provides a long-term solution that can be easily managed with regular maintenance.

Questions to consider for dust prevention

- What material are you adding moisture to?

- Should chemicals be added?

- Is the material moving or stationary?

DUST SUPPRESSION

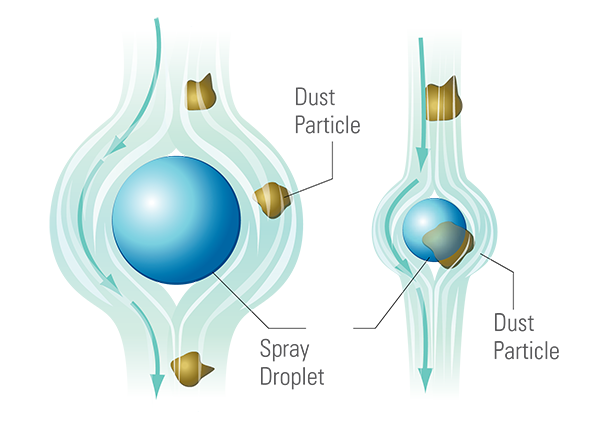

Dust Suppression refers to the principle of controlling already airborne particles and can be done alone or in support of dust prevention. Creating the correct droplet size is critical to success as it must be of equal size to the ore particles to merge and increase mass. This causes the particle to return to its material source or the ground.

What is the ore particle size?

Dust capture is most effective when dust particles merge with water drops of equivalent size.

Drops that are too large won’t collide with the smaller dust particles, and drops that are too small evaporate too quickly and release the captured dust particles. Understanding the particle size of the dust is critical to effectively designing a suppression system. You can use these general guidelines regarding dust particle size. However, further research may be necessary depending on the material and stage of the material in processing.