Processor Extends Shelf-Life of Meat Products by 40% and Achieves ALT-2 Status with Use of Automated Antimicrobial Spray System

Processor Extends Shelf-Life of Meat Products by 40% and Achieves ALT-2 Status with Use of Automated Antimicrobial Spray System

Problem:

North Country Smokehouse, a family-run smokehouse producing a wide variety of meat products, was achieving a shelf life of 45 to 50 days for their whole muscle and roll stock products. Like most processors, they wanted to extend the shelf life of their products. They also wanted to achieve ALT-2 status by adding an additional post-processing antimicrobial treatment for the first time. Maintaining a clean label was an additional goal.

Solution:

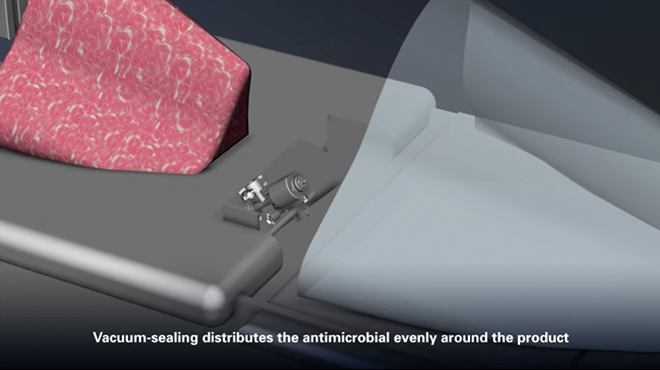

An AutoJet® Antimicrobial Spray System using the SLIC (Sprayed Lethality in Container) process from Spraying Systems Co. helped North Country Smokehouse meet its goals. The SLIC process is a food safety intervention which involves spraying an antimicrobial into a vacuum package before the meat product is inserted. Vacuum-sealing of the package distributes the antimicrobial evenly around the product – a process that has been validated by the USDA/ARS.

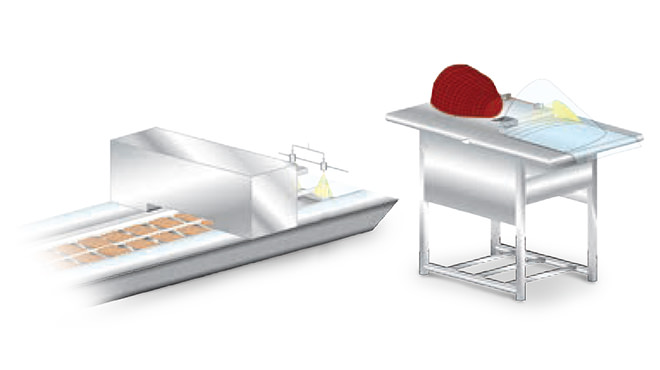

A two-channel AutoJet System controls the application of the antimicrobial agent on both a roll stock line and on a bagger. The system touch screen controller provides easy access to multiple recipes which allow for antimicrobial shot sizes ranging from 5 to 40 ml to be sprayed into the packages depending on the product being processed. Custom PulsaJet® spray nozzles constructed of FDA-approved CrN (chromium nitride) precisely dose the antimicrobial agent, lauric arginate diluted in a clarified liquid smoke. SprayCheck® sensors are used to confirm that each package receives the proper dosage.

Results:

The use of the AutoJet Antimicrobial Spray System has enabled shelf life to increase to 70 days from 45 to 50 – a 40% increase. ALT-2 status has also been achieved at a cost of $0.015 per pound for the lauric arginate and liquid smoke flavor. Typical log reductions have ranged from 2.3 for hams to 4.0 for kielbasa. The company’s clean label has remained unchanged since lauric arginate is a bacteriocide that is also considered a processing aid and does not need to be labeled at the levels being used.

For complete details of this case study click here to see the PDF version.