Pharmaceutical Manufacturer Reduces Cleaning Time by 80%; Equipment Cost Offset in Two Weeks

Pharmaceutical Manufacturer Reduces Cleaning Time by 80%; Equipment Cost Offset in Two Weeks

Problem:

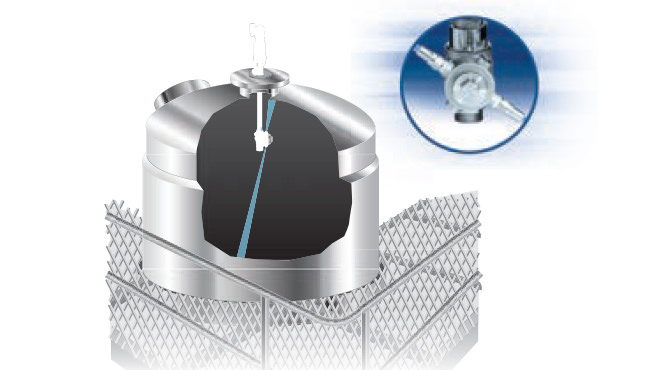

A Brazilian manufacturer of pharmaceutical solutions needed to clean two processing tanks. Each tank is 1900 mm in diameter and 2790 mm tall (6.25 ft dia. x 9 ft tall). The cleaning was previously done using spray balls but the process consumed too much water and took too long. The manufacturer needed to fi nd an alternative cleaning method that would reduce water use and downtime while maintaining the high standard for cleanliness required for the application.

Solution:

Spraying Systems Co.’s TankJet® AA190 tank cleaner solved the manufacturer’s problem. The TankJet unit features a rotating shaft and a rotating hub equipped with two solid stream nozzles that provide 360° cleaning of the entire tank. To properly position the nozzles within the tank, a special 317 mm (1 ft.) shaft is used. Operating at pressures up to 34 bar (500 psi), the TankJet AA190 provides the high-impact cleaning required by the pharmaceutical industry.

Results:

The TankJet® AA190 tank cleaners have reduced the volume of water needed from 2m³ (528 gal) to 0.45m³ (118 gal) per wash cycle. Cleaning time has also been reduced from 1 hour to 12 minutes even with stubborn residue. These process improvements are saving the manufacturer more than R$129,000 (US$64,500) per month. The cost of the new tank cleaning equipment was recouped in approximately two weeks. The customer’s goal of decreasing water use and downtime without compromising tank cleanliness has been achieved. In fact, water sample analyses determined that tanks were significantly cleaner after the change from spray balls to the TankJet AA190 cleaner.

For complete details of this case study click here to see the PDF version.