Bakery Eliminates Maintenance Downtime & Saves US$13,000 Monthly with Automated Spray System

Bakery Eliminates Maintenance Downtime & Saves US$13,000 Monthly with Automated Spray System

Problem:

An international manufacturer and distributor of baked goods needed to ensure that cakes did not shift after being set on cardboard plates for decorating, packaging and shipping to customers. Cake movement was resulting in damaged product that could not be sold and, consequently, a waste in materials.

The bakery determined that applying corn syrup to each plate as an adhesive eliminated cake slippage and significantly reduced damages. This method came with its challenges, though, as the viscous syrup required heating prior to being applied. In addition, excessive heat caused the syrup to become stringy and unusable, and over-application led to an extremely high amount of waste. To add to the bakery’s dilemma, the previously used automated spray system was designed for only one production line and featured outdated electronics that were not properly tuned. With polymer seals on its automatic nozzles, the abrasive corn syrup caused failures and subsequent downtime for maintenance and repairs. The system also produced syrup that was too hot and used 200% more than was necessary per cake base, contributing to excessive material waste and expenses. The need for two full-time attendants to monitor and clean the system significantly increased operating expenses.

Solution:

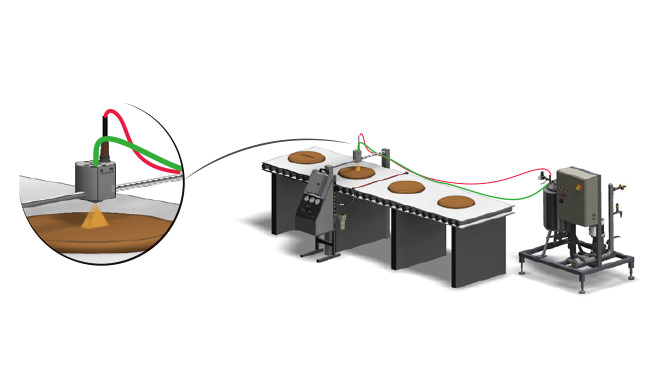

To deal with all of these challenges, the bakery’s engineers worked with Spraying Systems Co. to disable the original spray system controller, then test and install two AutoJet® Model 1550+ Modular Spray Systems to control the nozzles for two production lines. PulsaJet® AA10000JAU-10 air atomizing spray nozzles were chosen due to their response time and the application rate of the syrup. These also provided the value of adding air to atomize the syrup to both control the atomization width and break up the syrup droplets to speed cooling.

A 30-gallon (114 L) heated tank with agitator and jacketed hoses was used to ensure proper, consistent corn syrup temperature from the tank to the cake plates. With each AutoJet system controlling its own spray station, Precision Spray Control (PSC) ensured accurate amount and placement of the syrup with no waste, and the air atomizing spray nozzles improved syrup adhesion to the cake for better stabilization during the icing process.

Results:

With the modular, turnkey design of the new AutoJet® systems, the bakery was able to undergo installation without disrupting production. They experienced no electronic trigger failures or problems associated with the corn syrup’s location on the plates. The durability of the PulsaJet® spray nozzles also was much better than the previous nozzles. The bakery was able to completely eliminate downtime for maintenance while reducing personnel time to monitor and clean the system by 75%. The amount of corn syrup used was cut in half and due to improved stabilization, scrapped cakes were reduced by 90%. All of these improvements contributed to a payback period of only two months for the total investment on the systems.

For complete details of this case study click here to see the PDF version.