Aluminum Die Caster Increases Revenue by US$480,000 with Air Cannon Package

Aluminum Die Caster Increases Revenue by US$480,000 with Air Cannon Package

Problem:

An aluminum die caster needed to blow off and clean automotive parts after they had been machined and conveyed along a robotic production line. Two different systems – one using compressed air knives and another using a blower-fed system – had each failed to remove loose metal shavings from the parts. The metal shavings caused many of these parts to fail the pressure test and be sent to the reject area for re-testing. This also resulted in significant production downtime and additional labor costs.

The company sought a blow-off solution that would solve its high rejection rate, thereby increasing production and improving their bottom line.

Solution:

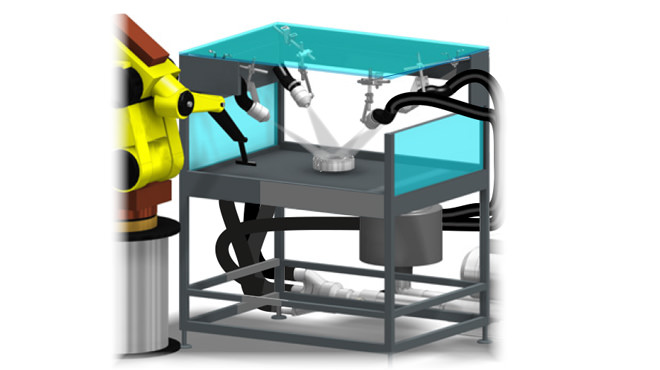

Spraying Systems Co. strategically mounted 26 various-sized WindJet® air cannons along the production line. Close attention was paid to the area where parts are machined, the area between machining and testing, and the test stations themselves. The air cannons, which featured anodized aluminum construction for corrosion resistance and long wear life, provided high-velocity air streams into the parts’ holes and indentations to remove any loose particles.

Four cast aluminum, 10HP regenerative blowers were installed to feed the air cannons. Using a dynamic operating principle that recycles a certain amount of air, the blowers powered all of the cannons with continuous, non-pulsating and oil-free air flow.

Results:

The installation of the WindJet® air cannon packages quickly resolved the issues the manufacturer was having with rejected parts, saving them significant time in re-working and re-testing. More importantly, this new solution helped increase its annual production by 80,000 parts, or 20%, and boost revenue by US$480,000. They also were able to eliminate the use of expensive compressed air. All of these benefits contributed to a payback period of only four weeks on their system investment.

For complete details of this case study, click here to see the PDF version.