Case Study

Automated Spray System Saves Building Products Manufacturer More than US$35,000 Annually

Problem:

Air atomizing nozzles were being used to apply a release agent to molds during the roof shake manufacturing process. The manufacturer was experiencing several problems. The release agent wasn’t applied uniformly on the molds. To compensate, the manufacturer increased the volume of release agent applied to ensure complete coverage. The nozzles sprayed continuously during production, which meant the areas between the molds were coated with release agent as well as the molds. Compressed air use was high and resulted in misting and worker safety issues. The manufacturer contacted Spraying Systems Co. to help improve the efficiency of the coating process, improve the work environment and reduce operating costs.

Solution:

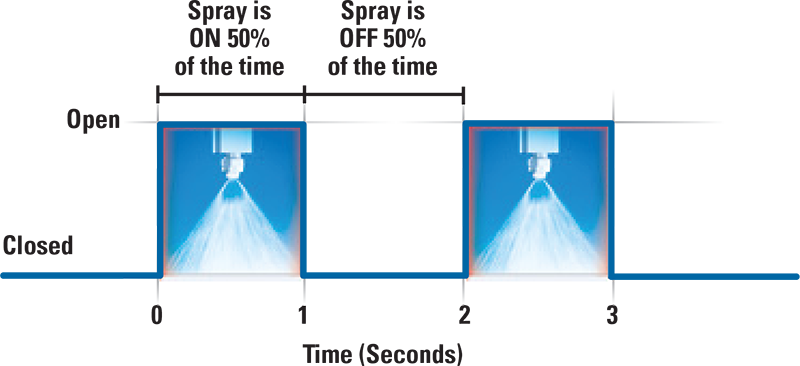

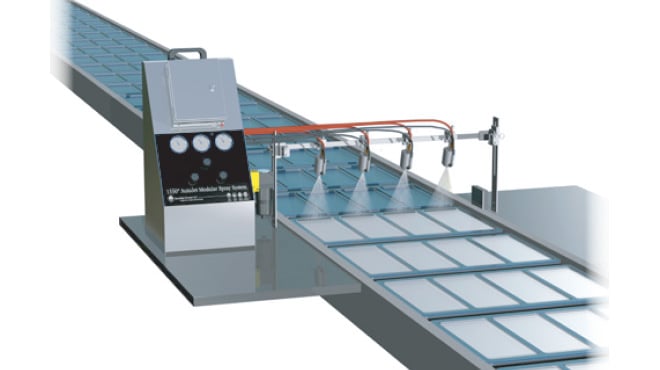

An AutoJet® automated spray system now applies the release agent. The system, controlled by an AutoJet Model 1550+ Modular Spray System, uses electrically-actuated hydraulic PulsaJet® nozzles to precisely apply the proper volume of release agent on each mold. Precision Spray Control (PSC) is used to adjust the flow rate based on operating conditions such as changing line speed. The system also uses sensors to detect the presence of the molds, ensuring the system only sprays when molds are present.

Results:

The AutoJet® automated spray system ensures precision application of the release agent on the molds. Over- and under-application problems have been eliminated and the release agent consumption has decreased by 25%. Costly compressed air and associated misting have also been eliminated resulting in lower operating costs, improved worker safety and a 40% reduction in maintenance time. The system exceeded the manufacturer’s expectation with a monthly savings of US$3,000 and a three-month return on investment.

For complete details of this case study click here to see the PDF version.