OSB Manufacturer Increases Production by 5% and Improves Quality with Mat Moistening System

OSB Manufacturer Increases Production by 5% and Improves Quality with Mat Moistening System

Problem:

An oriented strand board manufacturer needed better control over the addition of moisture to the OSB mat surface just before it entered the press. Adding the right amount of water enables the OSB to cure more quickly and evenly, ensuring consistent board quality with minimum press time.

The previous spray system was manually controlled and was unable to adjust flow rate to compensate for variations in line speed. Too much or too little moisture was often added, making product quality less predictable and sometimes extending press times.

Solution:

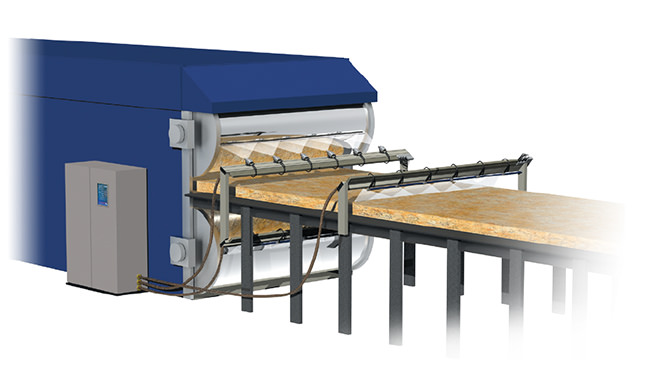

A PanelSpray®-MS system utilizing Precision Spray Control (PSC) has eliminated the manufacturer’s production problems. The system precisely adds from 0.0008 to 0.002 gal./ sq. ft. (0.033 to 0.081 liters/m2 ) of water to the mat and makes automatic adjustments for line speeds that vary from 40 to 140 ft/min (12.2 to 42.7 m/min).

The PanelSpray-MS system uses an AutoJet® Model 2250+ spray controller to automatically increase or decrease the flow of water through five PulsaJet® spray nozzles based on line speed. Controlling the flow using PSC rather than by adjusting liquid pressure allows the nozzles to maintain optimal spray angle and ensures uniform coverage of the water across the entire width of the mat.

Results:

Consistent surface moisture addition enabled the OSB producer to reduce press time while maintaining board strength and product quality. In addition to boosting production by more than 5%, the reduced press time also saved an estimated 10% of the energy used per press cycle. Together, these factors generated a payback period of approximately six months for the system.

For complete details of this case study click here to see the PDF version.