New Spray System Helps Beef Processor Improve Product Quality and Increase Revenue by US$60,000 Annually

New Spray System Helps Beef Processor Improve Product Quality and Increase Revenue by US$60,000 Annually

Problem:

A beef processor needed to apply water to beef patties prior to freezing in order to improve cooking and to maintain the proper weight. Government regulations require that the weight of the water added to the patties does not exceed the weight of the moisture lost during the freezing process. Line speed variations of up to 50% occurred regularly during processing. Unable to find a system that could automatically adjust to line speed and apply the proper amount of water, the processor was forced to skip adding water to the patties to offset the moisture loss in the freezer. Beef patties are sold based on weight and this caused a significant revenue loss for the processor.

Solution:

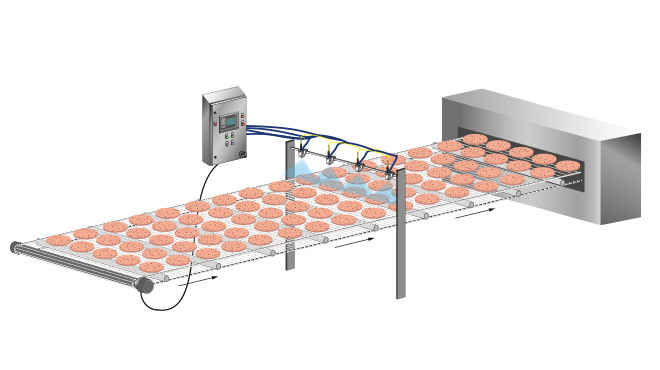

Spraying Systems Co. used an AutoJet® Spray System equipped with four PulsaJet® automatic spray nozzles to solve the processor’s problem. AutoJet Model 2250 Spray Controller adjusts the flow rate of the nozzles based on the line speed reported by the system’s conveyor speed sensor.

By adjusting the electrically-actuated PulsaJet nozzles, precise flow rate adjustments can be made instantaneously as line speed varies from 40 to 60 ft./min. (12 to 18 m/min.). Precision Spray Control (PSC) adjustments ensure the proper volume of water is added to each beef patty.

Results:

The AutoJet® Spray System provides an accurate, verifiable method for adding a precise volume of water to the beef patties. In addition to improving product quality for the processor’s foodservice customers, the spray system has a positive impact on revenue. Based on wholesale prices, the additional weight of the beef patties generates more than US$5,000 in additional revenue per month. The payback period on the AutoJet Spray System was less than six months.

For complete details of this case study click here to see the PDF version.