New Spray Nozzles Save 2.7 Million Gallons of Water for Beef Processor

New Spray Nozzles Save 2.7 Million Gallons of Water for Beef Processor

Problem:

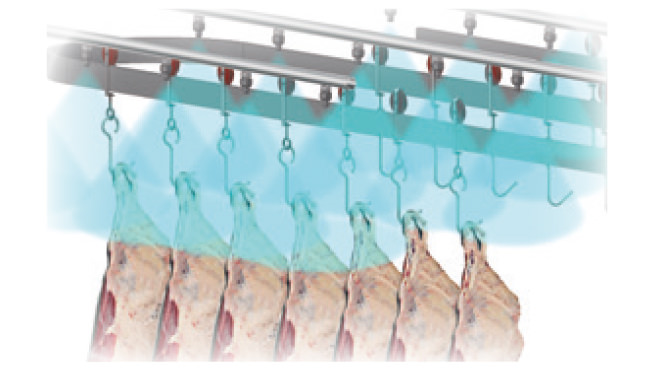

A leading processor and supplier of boxed beef products needed to intermittently spray cold water on fresh carcasses inside the initial chilling area of its plant, otherwise known as the “hot box.” This process, which is typically performed for about 14 hours, cools the carcasses, minimizes carcass shrinkage and helps prevent pathogen growth.

The previously used nozzles created excessive mist and condensation, which caused the rails and nozzles to gather water and freeze. The nozzles were also being struck by carcasses moving along the rails, throwing the spray patterns off target or breaking the nozzles. This damage required frequent maintenance, replacement and downtime. More importantly, any changes needed to be performed while maintaining acceptable shrink/swell parameters.

The processor sought a new spray system that would keep water consumption within the hot boxes at or below existing levels and eliminate water buildup and freezing issues. Controlling the carcass temperature would also help them avoid potential regulatory compliance or biological hazard issues related to contamination or bacterial growth.

Solution:

Spraying Systems Co. provided the UniJet® 23945, a spray nozzle that delivered a wide-angle, hollow-cone spray pattern with a thick annulus, for testing. This product consistently provided a narrow range of drop sizes, minimized misting and delivered an optimal transfer of water to the carcasses. The processor’s engineers immediately noticed a reduction in ice buildup on the rails, removing any concern for potential contamination to the carcasses. There were no significant changes in the carcass weight due to shrink or swell from the water.

The next phase of testing, which was modifying an entire hot box to monitor quality control issues, was also successful with a noticeable reduction of misting and continued lack of shrinkage. Without changing the header spacing, the spray nozzles were added directly to the existing drops, eliminating elbows used in the previous nozzle setup. The processor’s next step was installing this effective solution in 15 additional hot boxes.

Results:

The UniJet® hollow-cone spray nozzles performed exceptionally well for the beef processor, consistently chilling carcasses without misting. This led to no weight loss in their product and improved food safety.

With a total of 10,200 nozzles installed across 16 hot boxes, the company saved 5% (2,700,000 gallons [10,220,611 L]) in chilled water in the first year. This reduction resulted in a 5% energy savings from chiller use. While the original nozzles were being replaced at a rate of 3,000 to 4,000 per year, only five of the new nozzles had to be replaced in the first three months due to damage from moving carcasses and ice buildup. These reductions, combined with no longer having to clean rails and remove ice buildup between shifts, cut maintenance on the chilling nozzles to near zero. Total annual savings of up to US$25,000 resulted in a payback period of roughly 17 months on the company’s investment.

The success of this plant’s spray nozzle replacement project led the processor to switch out nozzles in additional locations.

For complete details of this case study click here to see the PDF version.