New Automated Spray System Helps Confectionary Manufacturer Solve Clogging Problem and Increase Production by 78%

New Automated Spray System Helps Confectionary Manufacturer Solve Clogging Problem and Increase Production by 78%

Problem:

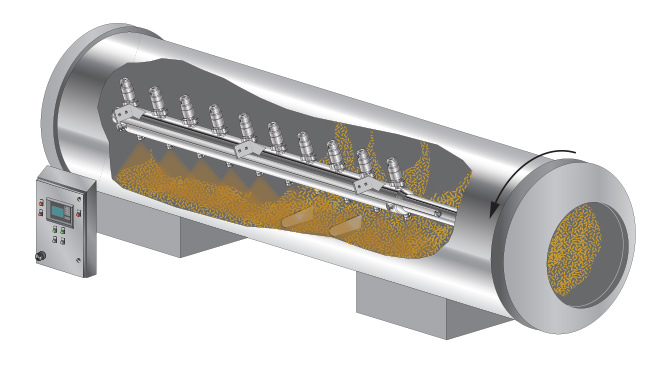

The Shanghai branch of Lotte Food coats almonds, hazelnuts and raisins with chocolate to create delicious treats. The coating takes place in a cylindrical tumbler. Compressed air was used to blow chocolate that was dripping from nozzles on to the nuts and raisins. This process was very slow – approximately eight hours were needed to coat and cool treats. Plus, the use of large drops and inefficient temperature control resulted in clogged nozzles and unscheduled downtime for maintenance.

Solution:

The Spraying Systems Co. solution was an AccuCoat® Pan Spraying System with a heated 63600 spray manifold. An AutoJet® Model Spray Controller monitors and automatically adjusts system components in the fully-jacketed system to ensure proper chocolate viscosity is maintained. The spray controller also facilitates quick production changeover by storing recipes for various products.

The spray manifold is equipped with ten air atomizing nozzles with clean-out needles to prevent clogging

Results:

The AccuCoat® Pan Spraying System has solved Lotte’s coating problems. Chocolate temperature is precisely controlled, clogging has been eliminated and batch changeover is quick. Lotte’s production of chocolate coated treats has increased by 78%. The equipment cost was recouped in just over one week. Lotte no longer plans to purchase additional equipment to meet its production goals since the single AccuCoat system has proven so effective.

For complete details of this case study click here to see the PDF version.