Food Safety Improved and Antimicrobial Use Slashed by 75% with AutoJet® Food Safety System

Food Safety Improved and Antimicrobial Use Slashed by 75% with AutoJet® Food Safety System

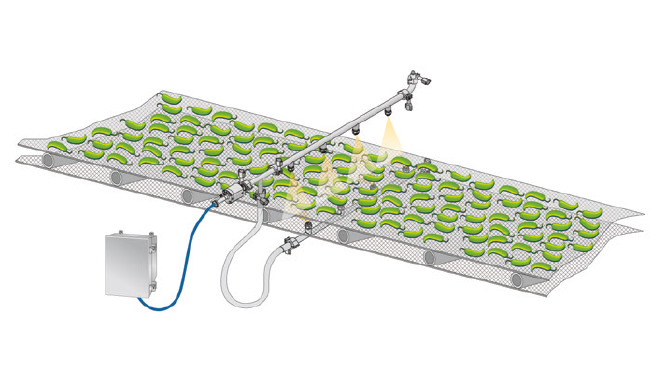

A food company was using drilled pipe mounted above a conveyor to apply an antimicrobial agent to peppers. Four AutoJet Food Safety Systems are now used to apply the antimicrobial agent to the peppers.

Problem:

A food company was using drilled pipe mounted above a conveyor to apply an antimicrobial agent to peppers. The flow from the pipe was constant and only one side of the peppers was coated with the antimicrobial. The company realized a more sophisticated approach to food safety was required and turned to Spraying Systems Co. for help.

Solution:

Four AutoJet Food Safety Systems are now used to apply the antimicrobial agent to the peppers. Stainless steel headers equipped with UniJet® spray nozzles are mounted above and below the conveyors to ensure the peppers are coated on all sides. AutoJet Model 1550+ spray controllers and electrically-actuated valves work in tandem to achieve Precision Spray Control (PSC). PSC enables automatic adjustments to flow rate based on changes in line speed and ensures the proper volume of antimicrobial is dispensed and waste is minimized.

Results:

The AutoJet Food Safety Systems have improved food safety for the food company. The peppers are now protected from harmful pathogens due to full coverage and consistent application of the antimicrobial. An additional benefit for the company is a dramatic 75% reduction in antimicrobial use now that the application rate is precisely controlled by the system. The Reduced use of chemicals has lowered operating costs and advanced the company's sustainability initiatives. The cost of the four systems was recouped in less than two years.

For complete details of this case study click here to see the PDF version.