Can Maker Boosts Production by 20% Annually with Heated Wax Spray System

Can Maker Boosts Production by 20% Annually with Heated Wax Spray System

A can manufacturer was using old technology to apply heated paraffin wax on metal sheets prior to stamping. Learn how they solved their wax application problems with the AccuCoat Heated Spray System.

Problem:

A can manufacturer was using old technology to apply heated paraffin wax on metal sheets prior to stamping. The wax acts as a lubricant and is critical to ensuring the can lids are defect-free. Adjusting the flow rate of the wax for different products was extremely difficult and the wax temperature varied. As a result, wax application was inconsistent, product reject rate was steadily climbing and downtime to troubleshoot the problems was increasing. The manufacturer turned to Spraying Systems Co. for assistance.

Solution:

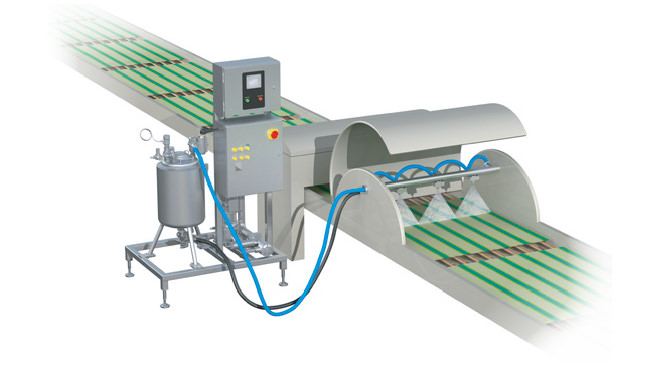

An AccuCoat® Heated Spray System solved the wax application problems. The fully-jacketed system consists of a heated spray header, three heated PulsaJet® electrically-actuated air atomizing nozzles and an AutoJet® spray controller. The system ensures the proper wax temperature is maintained until the time it exits the nozzles. Using Precision Spray Control (PSC), the application rate of the wax is automatically adjusted based on operating conditions such as changes in line speed. This eliminates the over- and under-application of wax and ensures uniform sheet coverage. In addition, operators can easily adjust flow rate via the HMI on the spray controller to accommodate the different coating weights required for various products

Results:

The installation of the AccuCoat® Heated Spray System has solved the can manufacturer’s quality control problems and the reject rate has been dramatically reduced. Consistent temperature control and precise flow rate control ensure consistent wax application on the metal sheets. In addition to lowering its scrap rate, the manufacturer has been able to increase production by 20% due to the elimination of downtime to troubleshoot application problems and equipment repair. The AccuCoat system also requires less power for operation than the previous system, providing both economic and environmental benefits. The cost of the new spray system was recouped in less than three months.

For complete details of this case study click here to see the PDF version.