Beverage Manufacturer Saves Over US$200,000 Annually

Beverage Manufacturer Saves Over US$200,000 Annually

Problem:

A Brazilian beverage manufacturer needed to dry cans and bottles on three packaging lines to ensure that expiration dates printed on the packages would adhere. Home-made air nozzles, headers made from crimped tubing and pipes with drilled holes were being used. The systems provided the required drying but used a large volume of costly compressed air.

Solution:

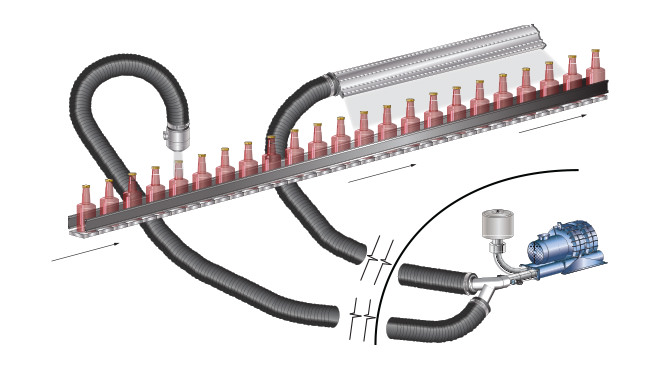

Spraying Systems Co.’s solution consisted of WindJet® Air Knife and Cannon Packages. Each system includes a 15HP blower with a 914 mm (36”) air knife and a 19 mm (3/4”) air cannon which powerfully dry the moisture on the necks and the caps of the bottles.

The WindJet Systems use low-maintenance regenerative blowers to produce clean, heated air. The low noise blowers are extremely energy-efficient. The air knives and air cannons deliver uniform, high-velocity air streams that dry the cans and bottles before printing.

Results:

The customer was spending more than US$200,000 annually to operate the compressed air systems prior to installing the WindJet® systems. The new systems have eliminated the need for compressed air for drying. Monthly savings of more than US$20,000 per month enabled the customer to offset the investment in the three WindJet systems in about three months.

For complete details of this case study click here to see the PDF version.