Bakery Reduces Scrap Rate by 80% with Automated Spray System

Bakery Reduces Scrap Rate by 80% with Automated Spray System

Problem:

Tiosa Supán, the largest commercial bakery in Ecuador and a supplier to major fast food restaurants, had difficulty ensuring that sesame seeds adhered to their products during baking. A spray system used air atomizing nozzles to apply mist to the unbaked dough to get the seeds to stick. However, spray pressure was adjusted manually to control the volume of water applied. At times, too little water was applied, resulting in seeds falling off the rolls. At other times, too much water was applied and prevented the dough from rising properly during baking. Excessive misting and dripping nozzles resulted in puddles of water on the floor which required daily clean up. In addition, shut-off needles and other components from the air atomizing nozzles required frequent maintenance.

Solution:

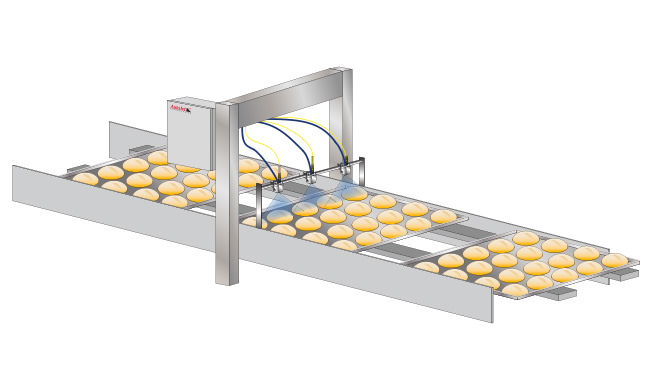

Spraying Systems Co.’s solution is an AutoJet® Model 1550 Modular Spray System with three hydraulic PulsaJet® automatic spray nozzles. The automated spray system utilizes Precision Spray Control (PSC) rather than pressure adjustments to precisely control the volume of water applied. The system adjusts automatically for variations in line speed, eliminating over- and under-application. When flow rate adjustments are needed for different baked goods, operators use the system control panel.

Results:

The AutoJet® Modular Spray System and PulsaJet® nozzles have enabled Tiosa Supán to improve product quality dramatically. Scrap rate has been reduced to just 2% – an improvement of almost 80%. In addition, using hydraulic PulsaJet nozzles instead of air atomizing nozzles has eliminated misting and dripping. Ongoing maintenance downtime has been reduced from 1 hour to just 15 minutes per day.

For complete details of this case study click here to see the PDF version.