Commercial Bakery Extends Bread Shelf Life by Seven Days; Saves Over US$19,000 using Modular Spray System

Commercial Bakery Extends Bread Shelf Life by Seven Days; Saves Over US$19,000 using Modular Spray System

Problem:

A large commercial bakery in South America needed to apply a preservative to its bread products before packaging to maintain a reasonable shelf life. The previous spray system applied the liquid preservative to the bread loaves using hydraulic nozzles at a constant pressure, making it difficult to adjust the application rate for different line speeds or products. This lack of control over the application rate resulted in customer complaints about the taste of the bread and the bakery experienced an unacceptable level of product returns.

Solution:

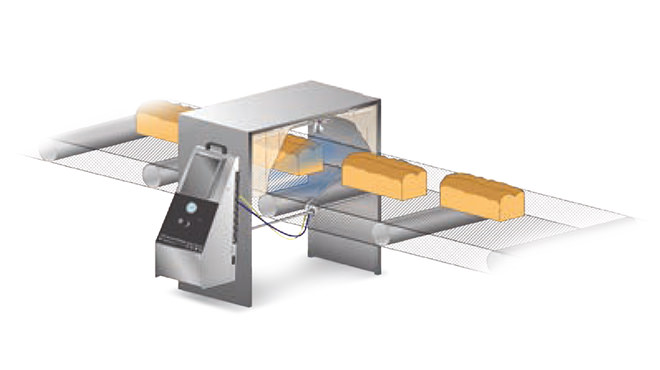

Spraying Systems Co.’s solution is an AutoJet® Model 1550 Modular Spray System with two hydraulic PulsaJet® automatic spray nozzles. The self-contained spray system includes an air-actuated diaphragm pump and utilizes Precision Spray Control (PSC) to precisely meter the volume of preservative applied. Flow rate adjustments for various bread products are easily made at the control panel and the system adjusts automatically for variations in line speed, eliminating over-application which can cause off-tastes.

Results:

The AutoJet® Modular Spray System and PulsaJet® nozzles have enabled the bakery to extend the average shelf life of its products by seven days. Customer returns have decreased by 60% and are no longer associated with either shelf life or taste. In addition, preservative usage has decreased significantly, generating annual savings of more than US$19,000.

For complete details of this case study click here to see the PDF version.