OSB Manufacturer Saves US$25,000 per Year by Recycling 500,000 Gallons of Wastewater

OSB Manufacturer Saves US$25,000 per Year by Recycling 500,000 Gallons of Wastewater

Problem:

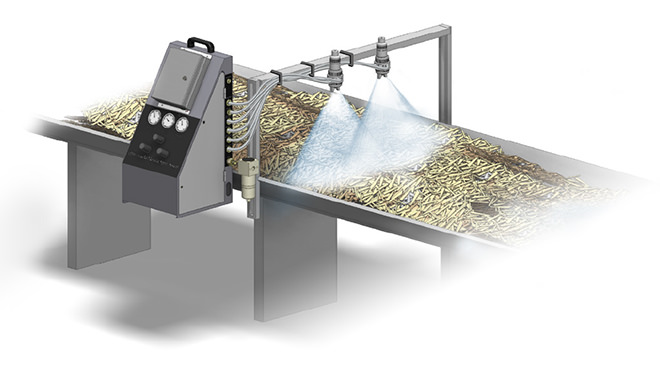

An oriented strand board (OSB) manufacturer needed a better way to spray particulate-laden wastewater generated by its environmental control systems. The wastewater is collected in tanks, then sprayed onto wood strands before they are dumped into large wet bins for sifting and separation. Reusing the 500,000 gallons (1900 m3 ) of wastewater created on site each year means it does not have to be disposed of as hazardous waste. The nozzles previously used to spray the wastewater slurry were continually clogging due to the nature of the liquid.

Solution:

Two AutoJet® 1550+ Modular Spray Systems with integrated air operated diaphragm pumps from Spraying Systems Co. solved the problem. The systems each control two 1/4VMAU variable spray air atomizing nozzles that allow the water to be continuously recirculated. The solid particles are suspended in the water so they do not accumulate in the line. To prevent clogging, the systems automatically cycle each nozzle on and off every fifteen minutes, which activates the nozzle’s clean-out needle to clear the spray orifice.

Results:

The AutoJet® Modular Spray Systems have eliminated clogging, enabling the manufacturer to reuse the wastewater in the production process. By diverting it from the waste stream, the manufacturer is saving US$25,000 per year in wastewater disposal costs, providing a payback period of approximately 17 months. Reusing the wastewater also enhances the facility’s sustainability efforts by keeping sludge that would result from the treatment process out of a landfill.

To see complete details of this case study click here to see the PDF version.