case study

Can Manufacturer Increases Revenue by US$4.2 Million Annually

Problem:

A can manufacturer needed to spray a protective coating to the outer welded seams on cans shipping overseas to prevent corrosion. Previously, only can interiors were sprayed since all shipments were domestic and exposure to harsh environmental conditions such as salt water was minimal. Without an efficient way to coat can exteriors, the manufacturer was unable to capitalize on the vast international market.

Solution:

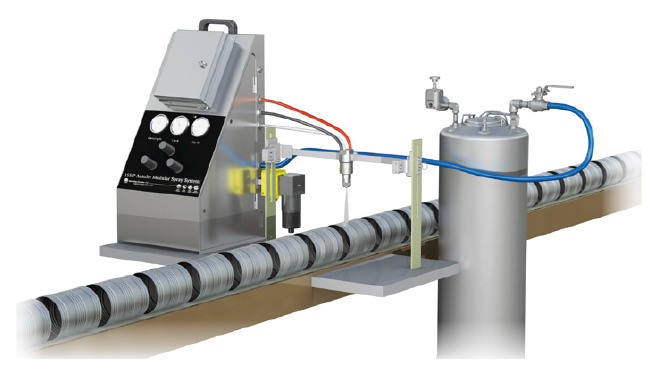

Spraying Systems Co.’s AutoJet 1550+ Modular Spray System now coats the outer seams on all cans shipping overseas. The spray controller regulates the flow of the protective coating to the spray nozzle mounted above the conveyor. An optical sensor detects when cans are properly positioned and signals the controller to trigger the nozzle to spray. The coating is applied directly on the can seam with minimal overspray. An agitator in the system’s 15-gallon (57-liter) stainless steel pressure tank helps achieve a uniform coating by properly blending the protectant before spraying.

Results:

The AutoJet 1550+ Modular Spray System efficiently coats the outside seams on all cans shipping overseas and effectively prevents corrosion. Coating the outside seams allowed the manufacturer to ship 30 million cans overseas in the first year and added US$4.2 million in revenue.

For complete details of this case study click here to see the PDF version.