Automated Spray System Paid for Itself in Two Weeks

Automated Spray System Paid for Itself in Two Weeks

Manufacturer continues to save more than US$240,000 annually

Problem:

A manufacturer of aluminum strip needed to apply a thin coating of oil on the strip during the coil finishing process. The lubricant facilitates forming operations and helps prevent corrosion.

The previous system utilized a header with seven flat spray nozzles spaced over the width of the 60” (1.5 m) sheet. Oil flow to the spray nozzles was manually controlled with needle valves. Operators adjusted flow to individual nozzles based on visual observation of the spray patterns. Work rolls helped spread the oil over the strip surface but the coverage varied widely from operator to operator and from coil to coil. Dry spots and excessively oily spots were common and resulted in rejected coils.

Solution:

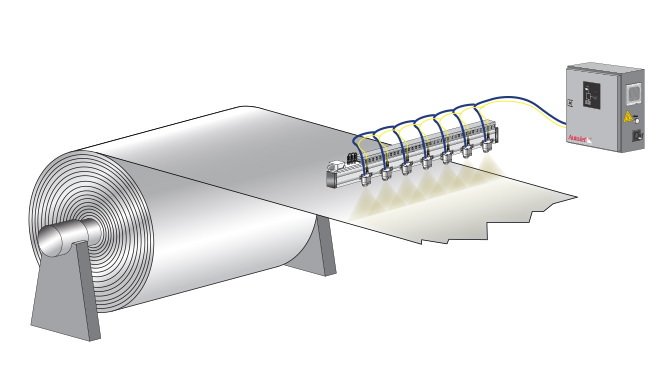

An automated spray system utilizing Precision Spray Control (PSC) now applies the oil and has eliminated coverage problems. The system applies a precise volume of lubricant (.0007 gallons/sq. ft.; .00265 liters/sq. m), makes automatic adjustments for line speed which varies from 400 to 900 ft/min (122 to 275 m/min) and allows individual nozzles to be controlled automatically to accommodate varying strip widths.

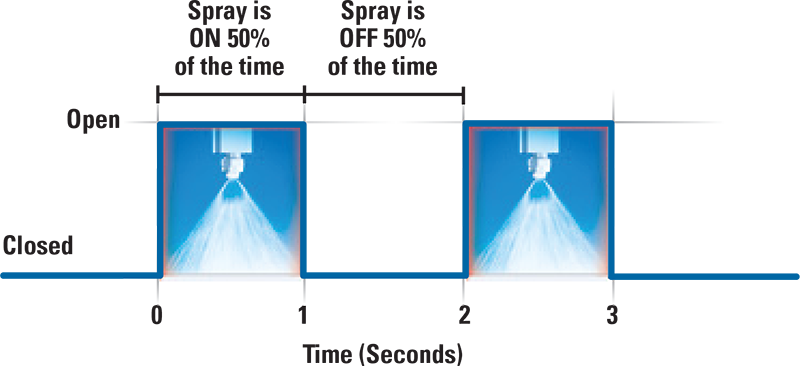

The Spraying Systems Co. solution uses an AutoJet® Model 2008 Spray Control Panel and a header with seven PulsaJet® spray nozzles. The spray control panel provides a convenient way to activate the spray nozzles at a specific frequency and duty cycle. Cycling up to 16,000 times per minute at a 40% duty cycle, the nozzles are able to maintain a consistent application rate despite line speed fluctuations. Controlling the flow using PSC rather than by adjusting liquid pressure allows the nozzles to maintain optimal drop size and spray angle and ensures uniform coverage of the lubricant across the width of the strip.

Results:

Since the AutoJet® Spray System was installed, coil rejections have decreased and lubricant use has been reduced. The hydraulic PulsaJet® nozzles have also eliminated misting and overspray, resulting in a significant decrease in maintenance costs. The customer reports the system cost was recouped in two weeks and monthly savings range from US$20,000 to US$30,000.

For complete details of this case study, click here to see the PDF version.