Steel Bar Manufacturer Eliminates Oil Overspray, Saves US$17,500 with Automated Spray System

Steel Bar Manufacturer Eliminates Oil Overspray, Saves US$17,500 with Automated Spray System

Problem:

A long steel manufacturer needed to spray a rust inhibitor on polished steel bars, however, its air atomizing spray system was creating misting, overspray and over-application of the oil. These issues resulted in messy equipment, an unsafe production area and an unhealthy environment for workers.

The company required a new spray system that would improve the precision of oil application and, in turn, reduce material and labor expenses.

Solution:

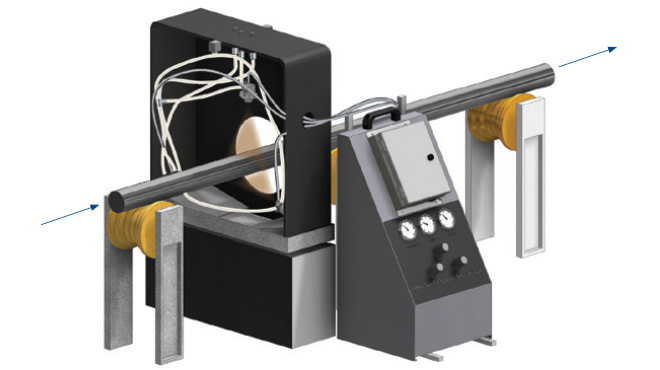

Following a test using hydraulic spray nozzles to check for spray pattern accuracy, Spraying Systems Co. installed an AutoJet® Model 1550+ Modular Spray System. Also included were three PulsaJet® AA10000AUH-104215 electrically actuated spray nozzles and UniJet® PWMD spray tips.

As the 7/8- to 3-inch-diameter steel bars passed through the spray station, the Model 1550+ system was triggered by a photoelectric thru beam sensor to start and stop the spray nozzles. Mounted to deliver uniform, consistent oil coverage, these hydraulic nozzles were able to achieve a low flow rate of 1 to 4 gallons/hour (3.8 to 15 liters/hour) and steady liquid pressure of 30 psi (2 bar).

Results:

By evenly coating the steel bars without misting or overspray, the AutoJet® system and its PulsaJet® hydraulic nozzles were able to save the manufacturer significant costs in rust inhibitor consumption, air compressor operation and maintenance, labor for cleanup, and materials to absorb spills and excess spray. All of these reductions totaled US$17,500 annually, resulting in a payback period of less than a year for the new spray system.

The company also was able to improve its sustainability efforts by making the work environment safer and healthier for employees through the elimination of overspray and airborne oil.

For complete details of this case study click here to see the PDF version.