Can Manufacturer Saves More than $500,000 Annually by Reducing Compressed Air Usage

Can Manufacturer Saves More than $500,000 Annually by Reducing Compressed Air Usage

Problem:

A manufacturer of three-piece cans wanted to reduce its compressed air usage to save money and qualify for a government grant awarded for energy savings. Like most can manufacturers, they were faced with multiple cooling and drying applications and had historically used a variety of compressed air nozzles and open pipes to accomplish these operations.

Solution:

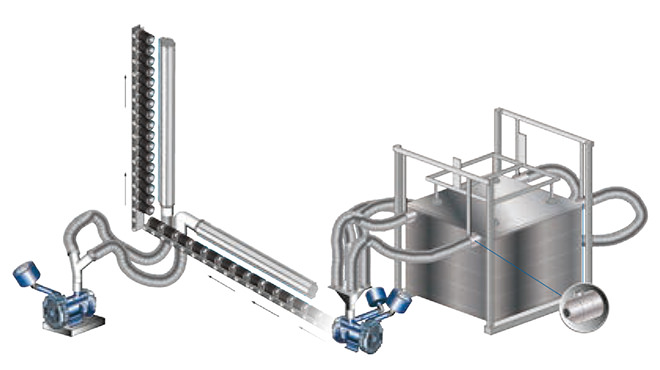

- At the sheet separator, a 3HP blower with four air cannons now prevents steel sheets from sticking together when lifted into place on the conveyor belt. This system replaced six compressed air nozzles

- After the cans are formed and welded, a 20HP blower with a 48” air knife is used to cool the weld seam, replacing a pipe with drilled holes emitting compressed air

- The same 20HP blower powers a 96” air knife that pushes the cans firmly against a vertical magnetic belt that takes them for further processing. The air knife replaced another homemade pipe with holes

- Prior to packaging, a 5HP blower and four 6” air knives are used to remove all moisture from the cans, replacing compressed air nozzles

Results:

The WindJet® Air Knife packages, powered by powerful, low maintenance regenerative blowers, produce high-velocity streams of clean, heated air and have eliminated the need for compressed air in these four operations. The systems operate 24/7 and have decreased plant compressed air use by nearly 3,800 scfm, generating electricity savings of more than $500,000 each year – including the cost of operating the new blowers. The payback for these systems was less than one month and the can manufacturer has qualified for a government energy grant.

For complete details of this case study click here to see the PDF version.