Arab Medical Equipment Company (AMECO) sprays silicone into syringe barrels to help the plungers glide during use. The previous method cycled barrels under an air atomizing nozzle. Each machine is capable of producing 15,000 barrels per hours, but the system could only accurately coat about 9,000 per hour. In addition, silicone waste was high because of poor transfer efficiency.

Solution:

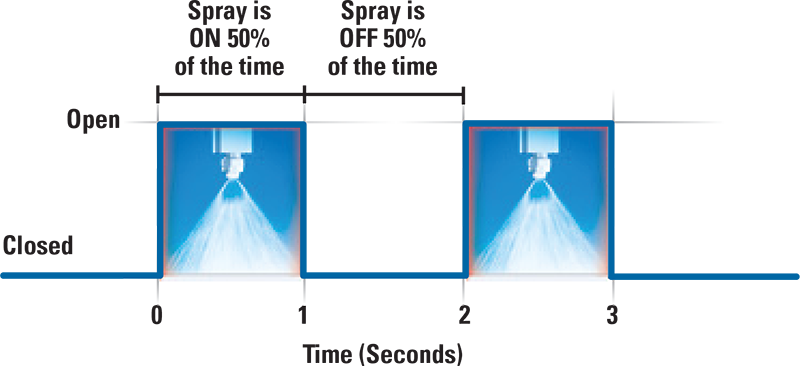

The problem has been solved with three AutoJet spray systems - one on each line. Each system uses an optical sensor to detect barrels and sends a signal to the AutoJet spray controller, which in turn, triggers the PulsaJet® electrically-actuated air atomizing nozzle to spray. Using Precision Spray Control (PSC), the precise volume of silicone is applied with minimal waste even when line speed varies. Each cycle takes just six milliseconds at the fastest line speed.

Results:

The AutoJet spray system achieved the production goal of 15,000 syringe barrels per hour on all three machines. This 67% increase will enable the company to produce an additional 51 million syringe barrels annually. The precision application provided by the system has also resulted in a 30% reduction in silicone consumption. The cost of the AutoJet system was recouped in less than four months.

For complete details on this case study, click here to download the PDF version.