Chest Cleaning

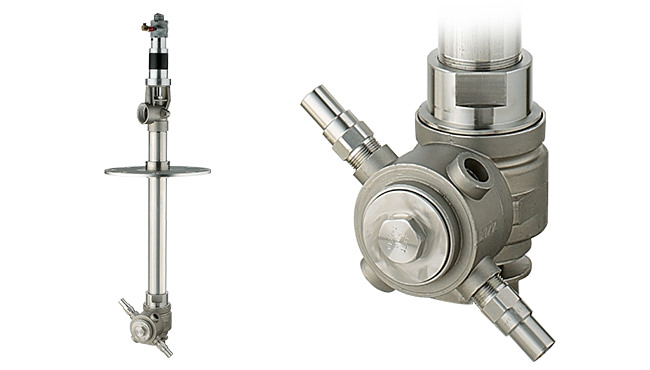

Paper and tissue manufacturers use spray technology from Spraying Systems Co. to automate their chest and tank cleaning processes. Automated chest cleaning improves worker safety, reduces cleaning time and decreases the use of water and chemicals. Our TankJet® solutions are available in a wide range of sizes to meet all needs.

There are many reasons to automate cleaning of chests and tanks in your mill, but the two most important are to save water and improve worker safety. Manual cleaning of chests and tanks wastes millions of gallons of water. It also exposes workers to dangerous chemical fumes and requires entry into large chests or cleaning from small areas above the tanks. Automating the cleaning of stock and mixing chests, coating and broke chests and other vessels can help you conserve water, operate more sustainably and reduce the risk of worker injury and illness. Additional benefits include:

- Thorough, consistent, repeatable cleaning

- Decreased downtime for cleaning – chests and tanks can be returned to service more quickly

- Workers can be deployed to other, safer tasks

Find out how easy and economical it is to automate:

- Request a free, on-site chest and tank cleaning evaluation. Your local spray expert will assess your current cleaning methods. After the evaluation, you will receive suggestions on how best to automate cleaning along with projected costs and payback periods for TankJet® equipment

- Some of our TankJet units are available for a free trial period so you can experience the benefits automation can bring to your mill before you purchase – just let us know you’re interested