Enhance Efficiency & Compliance

Gas Cooling for Cement

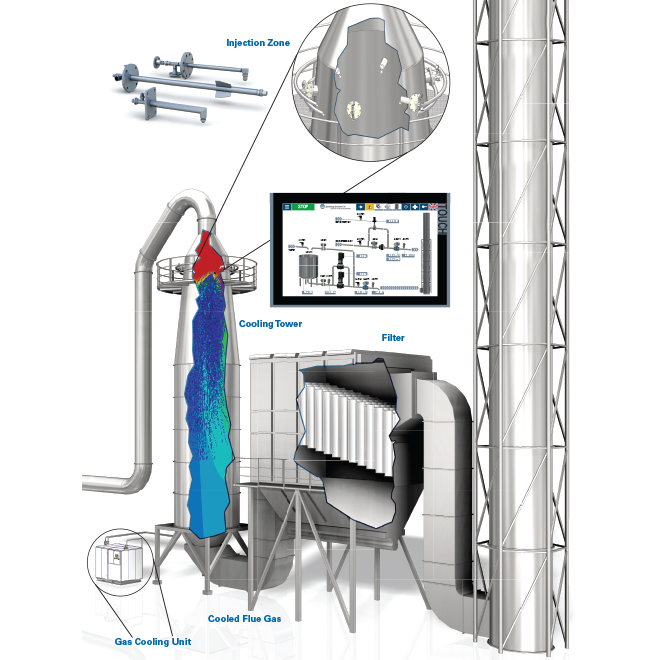

Discover precision-engineered gas cooling solutions designed to meet the cement industry's specific needs. Our cutting-edge system efficiently tackles high temperatures and dust emissions, critical for maintaining top-tier clinker quality and operational efficiency. Featuring an advanced closed-loop control system that seamlessly integrates nozzles, pumps, and sensors, it delivers unparalleled accuracy in gas temperature and volume management. Rapid adaptation to temperature changes ensures continuous compliance with stringent environmental standards while fostering consistent plant operations. By choosing our gas cooling solutions, cement plants benefit from a significant boost in productivity, substantial operational cost savings, and a notable reduction in environmental impact. Step into a future of cleaner, safer, and more efficient cement production with our optimized gas cooling technology.

Key Features:

- Low energy consumption

- Low maintenance

- Turnkey system

- Reliable performance

- Fast reaction to changing process conditions

- Integrates into existing process controls

- Closed-loop temperature control for constant outlet temperature

- System integrity check to detect clogged or worn spray nozzles

- Failure backup system with double components

- Optimized atomizing gas regulation

- One project partner from feasibility studies (CFD) to commissioning

Gas cooling systems are pivotal for cement plants, providing a solution that directly tackles the industry's unique challenges, such as managing high temperatures and controlling dust emissions. These systems ensure optimal clinker quality and efficiency by offering precise temperature control. This is critical in cement manufacturing, where maintaining the right temperature range is essential for product quality and prolonging equipment lifespan. Additionally, these systems play a vital role in reducing emissions, helping plants comply with stringent environmental regulations and avoid fines, making them a cornerstone of sustainable operation.

FloMax, SteamMax & Atomizing Nozzles

- FloMax® nozzles efficiently atomize gas in diverse applications with minimal energy use.

- Patented designs enable extremely small drops, enhancing process efficiency.

- A Series nozzles offer three-stage atomization for uniform drops in cooling and pollution control.

- Anti-Bearding and X Series adapt to high dust and low-pressure needs, respectively.

- H, S/SMAXB Series and Eco variant cater to specific gases and eco-friendly operation.

Gas Cooling Lances

- Standard and custom injectors, lances, and quills enhance spray performance, impacting operational costs.

- Offerings include tailored solutions for tank cleaning, gas cooling, and other applications, ensuring optimal nozzle integration.

- Lances available in various angles with customization options like cooling jackets and retractable versions for flexibility.

- Custom tank cleaning lances for TankJet® with adjustable features for quick delivery and performance optimization.

- Global support in nozzle/injector selection, design, and validation with CFD modeling, backed by a proven track record and international compliance.

CFD Modeling

- Utilize FEA, CFD, and FSI for detailed simulations of fluid and spray behaviors, addressing complex application challenges.

- Apply modeling for spray optimization and innovation, especially where lab testing is impractical due to environmental, safety, or cost constraints.

- Offer both standard and custom models, with custom ones integrating precise lab data for realistic simulations of spray dynamics and specific phenomena.

- Custom models ensure accurate representation of physical processes and validation, speeding up project completion for operational optimization.

- Support diverse applications including industrial equipment flow, spray distribution, pollution control, and cooling processes.