Waste Hauler Saves More Than US$60,000 Annually on Tank Cleaning Expenses

Waste Hauler Saves More Than US$60,000 Annually on Tank Cleaning Expenses

Problem:

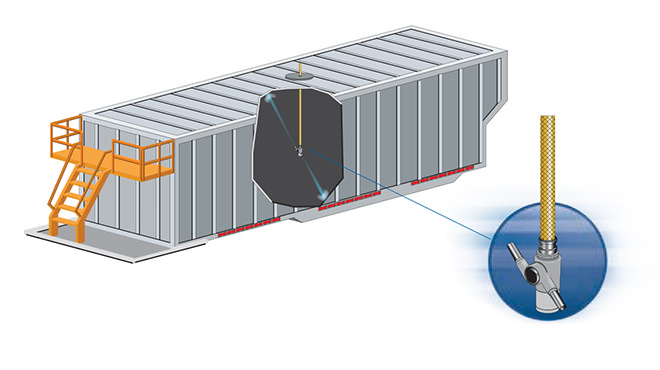

Sprint Waste Services needed to quickly and effectively clean large “frac” tanks used in the oil and gas industry. The box trailer tanks, which measure 41’ long x 9’ high x 8.5’ wide (12.5 m long x 2.74 m high x 2.59 m wide), hold a mud solution used for high-pressure hydraulic fracturing of rock layers containing petroleum and natural gas. The tanks need to be cleaned periodically, but the remote location of the oil fields makes this difficult. The tanks were previously transported approximately 65 miles (105 km) to a cleaning station where they were cleaned manually – a time-consuming and expensive task.

Solution:

Spraying Systems Co.’s TankJet® 360 tank cleaner solved Sprint’s problem. The TankJet unit provides effective cleaning of the entire box trailer on-site. Water is pumped to the tank cleaner at 165 psi (11.4 bar) with a flow rate of 160 gpm (606 lpm). The powerful impact of TankJet 360 thoroughly cleans the interior of the frac tank in 90 minutes – up to 50% faster than manual cleaning – enabling the tanks to be back in service very quickly.

Results:

The on-site automated tank cleaning system has provided several important benefits for Sprint Waste Services. The time and expense of hauling the frac tanks to a remote cleaning facility have been eliminated, along with the labor for manual cleaning. Together, these benefits save an estimated US$400 per tank cleaning. Up to 10 tanks are cleaned each day for an annual savings of approximately US$60,000. The cost of the TankJet® 360 was recouped by Sprint Waste Services in less than one week. After the first successful TankJet 360 installation, the company purchased two additional TankJet tank cleaners for frac tank cleaning.

For complete details of this case study click here to see the PDF version.