Sulfuric Acid Manufacturer Increases Revenue by More Than US$40,000 per Year with New Spray Injectors

Sulfuric Acid Manufacturer Increases Revenue by More Than US$40,000 per Year with New Spray Injectors

Problem:

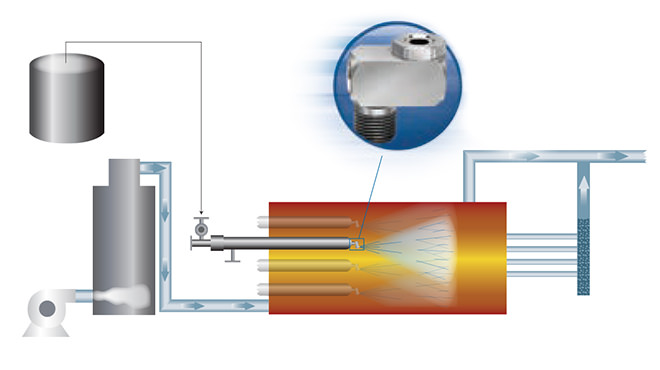

Jordan Phosphate Mines Co. (JPMC), a leading producer of sulfuric acid, was using steam-jacketed injectors to spray molten sulfur in furnaces to form sulfur dioxide (SO2). Four injectors were used in each furnace. The injectors had an internal bellows for thermal expansion. However, steam leaked from the bellows and compromised worker safety. Excess moisture was also created which increased maintenance time.

Solution:

Spraying Systems Co. developed a new injector design for JPMC. A special packing gland design is used, eliminating the need for the bellows joint and the leaking problem. The injectors are steam-jacketed and equipped with hydraulic BA WhirlJet® nozzles that produce a hollow cone spray. In addition, the injectors are designed to be more space-efficient to help simplify and reduce maintenance time.

Results:

JPMC has been using the injectors for more than two years and has experienced trouble-free operation. Steam leaks have been eliminated, worker safety improved and maintenance time decreased. As a result, production time has increased and is valued at approximately US$42,000 per year. In addition, the injectors from Spraying Systems Co. cost less than the previously used injectors, an additional savings of US$12,000.

For complete details of this case study to see the PDF version.