New System Increases Number of Trucks Cleaned Daily & Reduces Downtime for Nozzle Repairs

New System Increases Number of Trucks Cleaned Daily & Reduces Downtime for Nozzle Repairs

Problem:

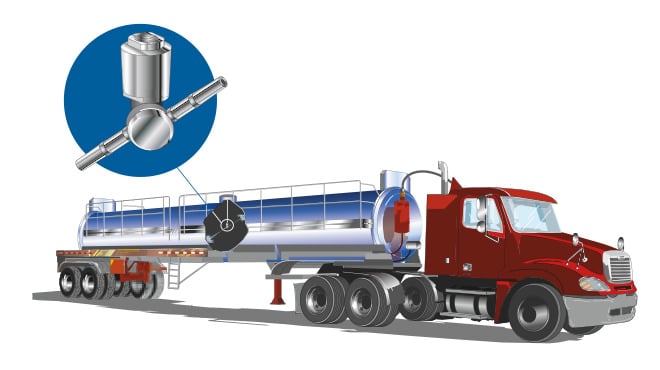

Industro Equipment, an OEM located in the southeast United States, needed to improve the performance of truck wash racks for an important customer. The application required cleaning corn syrup from the internal surfaces of 40’ (12 m) tanker trucks.

The previously used rotating tank cleaning nozzles were not able to clean the ends of the tankers because of inadequate throw distance. Also, the nozzles could not be used with steam – an option the end user needed. Additional problems with the nozzles included wear life issues requiring the nozzles to be rebuilt frequently and high consumption of water for each cleaning cycle.

Solution:

Spraying Systems Co.’s TankJet® tank cleaning nozzles solved the end user’s tanker cleaning problems. The high-temperature, stainless steel TankJet 65-HT tank cleaner was used in wash bays where steam preheating was required since it can withstand temperatures up to 500°F (260°C). In wash bays requiring only hot water for effective cleaning, the TankJet 80 tank cleaner was used. Both tank cleaners use high-impact solid stream nozzles and perform reliably day in and day out.

Results:

Industro Equipment’s customer has been extremely pleased with the performance of the updated truck wash racks. In addition to providing the ability to use steam when necessary, cleaning time for each tanker truck has decreased by more than 15 minutes. The faster cleaning time significantly reduces water use and allows an average of three additional trucks to be washed per shift. In addition, the TankJet® nozzles last four times longer than the previous nozzles before maintenance is required and the rebuild time is 75% faster. The result for Industro Equipment has been positive as well. The company was selected to provide multiple new truck wash systems for the same customer in another city.

For complete details of this case study click here to see the PDF version.

-in-dia,-d-,-with-the-tankjet-80-from-spraying-systems-co-660x370.jpg?h=370&w=660&la=en&hash=D32B7801C180735BAC8D11FC17EAA3B1)