Food Processor Saves More Than US$35,000 Annually with Automated Spray System

Food Processor Saves More Than US$35,000 Annually with Automated Spray System

Problem:

A Middle Eastern food processor was using powdered natamycin, a preservative and mold inhibitor, to enhance the quality of their shredded cheese and extend shelf life.

The company wanted to use liquid natamycin instead of the powder. The powder was difficult to handle, tended to spill and created dust which adhered to the processing equipment. However, the processor was having trouble finding a system that could apply the required low dosage without using compressed air.

Solution:

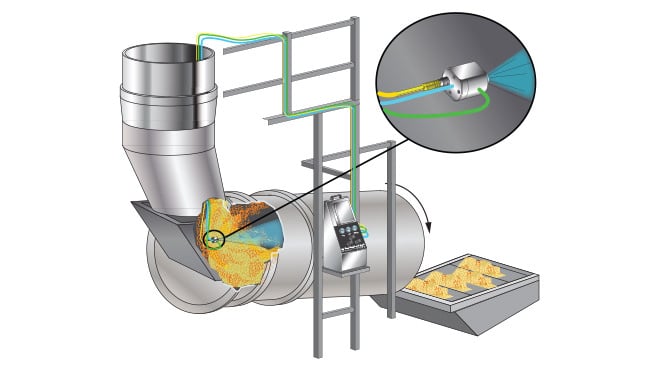

The Spraying Systems Co. solution applies liquid natamycin with an AutoJet® Model 1550 Modular Spray System and a hydraulic PulsaJet® nozzle. The AutoJet system ensures that a low dosage of the preservative is applied to the cheese with minimal waste. Flow rates can be automatically adjusted to correspond with the volume of cheese being produced.

Results:

The AutoJet® spray system enabled the successful transition from powdered to liquid natamycin. A low volume of natamycin is now applied to the cheese uniformly. The processor is saving approximately US$35,000 annually and experienced payback on the new system in less than two months.

For complete details of this case study click here to see the PDF version.