Food Ingredient Manufacturer Cuts Tank Cleaning Time by 75% and Offsets Equipment Cost in Less Than a Week

Food Ingredient Manufacturer Cuts Tank Cleaning Time by 75% and Offsets Equipment Cost in Less Than a Week

Problem:

A leading producer of spices and seasonings needed to thoroughly clean the interior surfaces of its mixing tanks between batches. Manually cleaning the powder residue from the blenders with high pressure hoses and brushes took workers an hour or more and produced inconsistent results. The cleaning process was a significant labor expense since three batches per shift were being produced during three shifts per day. The production downtime also resulted in significant lost revenue.

Solution:

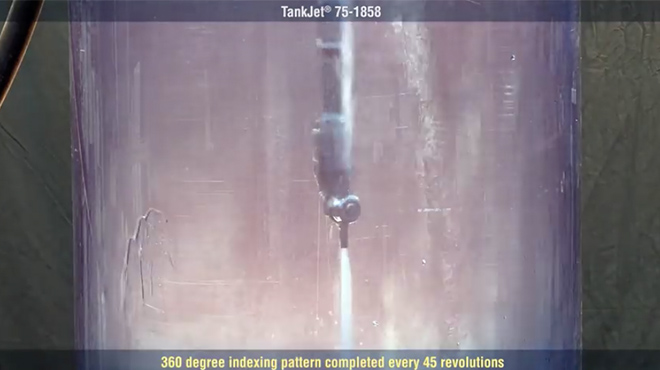

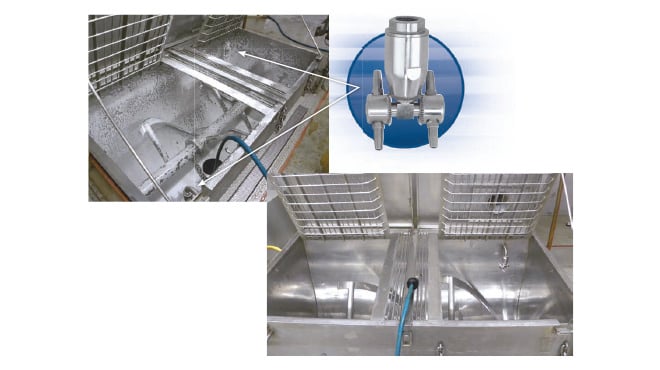

Our TankJet® 75 tank cleaner solved the customer’s problem. Two TankJet 75 units, positioned in opposite corners of the blender, provide effective cleaning. Shadowing, caused by the ribbon blade and other internal obstructions, is overcome by the use of two tank cleaners that ensure all surfaces are thoroughly cleaned. Hot water is pumped to the tank cleaners at 50 psi (3.4 bar) with a flow rate of 8 gpm (30 lpm). The powerful impact of the water jets ensures repeatable results with every cleaning cycle.

Results:

The automated tank cleaning process has saved an estimated CAD$25,000 in labor expense. In addition, TankJet units have reduced the time required for cleaning the mixers from one hour to 20 minutes. This reduction in downtime allows for the production of one additional batch of spices per shift. Together, these factors paid for the investment in tank cleaning equipment in less than one week.

For complete details of this case study, click here to see the PDF version.