case study

Corn Processor Increases Production by 33% & Cuts Steam Use in Half with New Spray Nozzles

Problem:

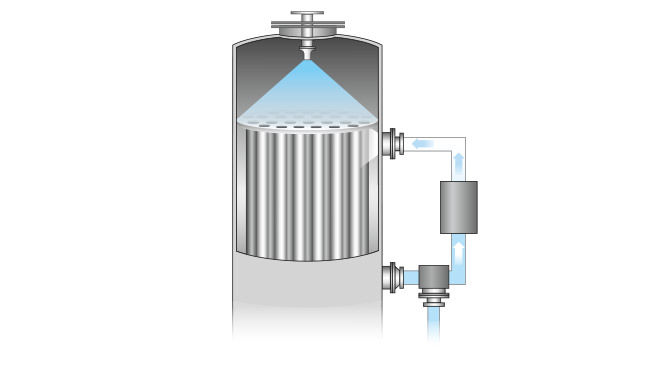

A corn processor wanted to improve liquid dextrose production efficiency. Falling film evaporators used steam to evaporate some of the water content in the liquid dextrose to increase its concentration. The dextrose was applied to the evaporator’s distribution plates via drilled holes in pipes. The application process was inconsistent and uneven, and required a lot of steam to achieve the necessary level of evaporation. The processor was looking for a way to increase production of the dextrose and reduce steam consumption.

Solution:

Spraying Systems Co.’s solution uses DistriboJet® full cone nozzles to apply the liquid dextrose to the distribution plates instead of drilled pipes. The nozzles uniformly apply the dextrose across the width of the distribution plate. In addition, the liquid is atomized as it passes through the nozzles. Smaller droplets are produced, improving evaporation efficiency and reducing steam use. The use of the high-capacity DistriboJet nozzles has also enabled an increase in the feed rate and yield of the liquid dextrose.

Results:

The improved efficiency of the new system has allowed the corn processor to achieve its production and energy conservation goals. The DistriboJet nozzles operating at 1,000 gpm (3,785 lpm) have led to a 33% increase in yield and provide uniform coverage of the evaporator’s distribution plates. Evaporation efficiency is greatly improved, load on system compressors is reduced and boiler steam use has decreased by 50%.

For complete details of this case study click here to see the PDF version.