Wine Bottle Manufacturer Saves More than US$161,000 on Compressed Air with New Blower System

Wine Bottle Manufacturer Saves More than US$161,000 on Compressed Air with New Blower System

Problem:

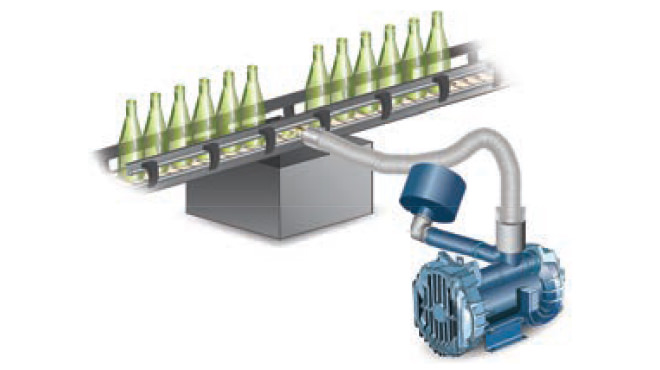

A manufacturer of wine bottles needed to blow broken glass off production lines. Homemade air nozzles fabricated from crimped stainless steel tubing were being used. The nozzles were able to remove the glass from the conveyor lines but they were extremely expensive to operate because they consumed a large volume of compressed air.

Solution:

Spraying Systems Co.’s solution is WindJet® Air Cannon packages, which are installed on each of the seven production lines in the plant. Each system consists of a 2.5HP blower and a 1” air cannon to powerfully blow broken glass from the conveyor. The regenerative blowers are low maintenance, low noise, energy efficient and produce clean, heated air. WindJet Air Cannons deliver a uniform, high-velocity air stream that is able to easily blow broken shards of glass away from the production line.

Results:

Prior to installing the WindJet® Air Cannon packages, the customer had been spending almost US$170,000 annually on compressed air. The annual operating expenses for the WindJet Air Cannon packages are about US$8,500 – a savings of more than US$161,000. The cost of the new system was recouped in just over one month.

For complete details of this case study click here to see the PDF version.